How to Measure a Hydraulic Cylinder? A Step-by-Step Guide

To measure a hydraulic cylinder, determine the stroke length and the bore diameter. Measure the rod diameter as well.

Hydraulic cylinders are essential components in many mechanical systems. Precise measurement is crucial for maintenance, repair, or replacement. Start by identifying the stroke length, which is the distance the rod travels. Next, measure the bore diameter, the internal width of the cylinder.

Lastly, determine the rod diameter. These measurements ensure you select the right parts and achieve optimal performance. Accurate measurements prevent potential operational issues and costly downtime. Understanding these basics helps in maintaining hydraulic systems effectively. Proper measurement techniques are vital for the longevity and efficiency of hydraulic cylinders.

Introduction To Hydraulic Cylinders

Hydraulic cylinders are essential components in various machinery. They convert hydraulic energy into mechanical energy. This process is crucial for many industrial applications.

Importance In Machinery

Hydraulic cylinders are vital in heavy machinery. They provide the force needed for lifting and moving heavy loads. They are used in construction equipment, manufacturing, and many other fields.

- Excavators

- Loaders

- Cranes

Without hydraulic cylinders, many machines cannot function. They ensure smooth and efficient operations.

Basic Components

Understanding the basic components is important for measuring a hydraulic cylinder. Here are the main parts:

| Component | Description |

|---|---|

| Cylinder Barrel | The main body that holds the pressure. |

| Piston | Moves back and forth inside the barrel. |

| Rod | Connected to the piston, extends out of the barrel. |

| Seal | Prevents hydraulic fluid from leaking. |

Each part plays a crucial role. Knowing these parts helps in accurate measurement.

Preparation For Measurement

Before measuring a hydraulic cylinder, preparation is key. Proper preparation ensures accurate results and safety. Follow these steps to get started.

Safety Protocols

Safety should always come first. Follow these safety protocols:

- Wear protective gear like gloves and goggles.

- Ensure the hydraulic system is off.

- Release any stored pressure in the system.

- Work in a well-ventilated area.

Tool Selection

Choosing the right tools is essential for accurate measurement. Use the following tools:

- Caliper: For precise measurements of the cylinder’s diameter.

- Tape Measure: For measuring the cylinder’s length.

- Wrench: To remove any parts if needed.

- Notepad and Pen: To record measurements.

| Tool | Purpose |

|---|---|

| Caliper | Measure cylinder diameter |

| Tape Measure | Measure cylinder length |

| Wrench | Remove parts if needed |

| Notepad and Pen | Record measurements |

Identifying Cylinder Types

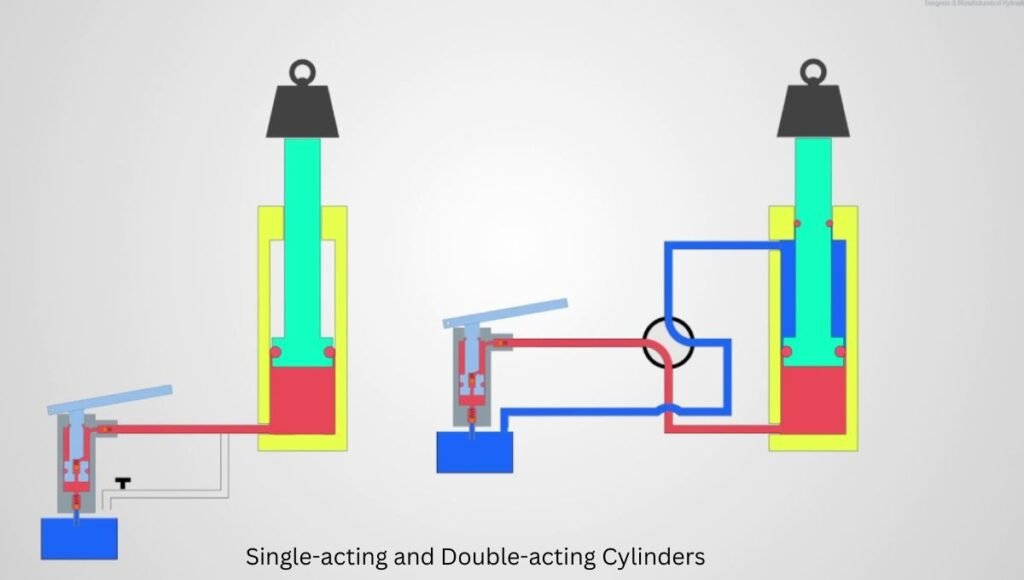

When measuring a hydraulic cylinder, it is crucial to identify the cylinder type. Different types have unique characteristics and measurement techniques. This section will help you understand the differences between single-acting and double-acting cylinders.

Single-acting

Single-acting cylinders use hydraulic fluid to move the piston in one direction. They rely on a spring or external force to return the piston to its original position. These cylinders have one port for hydraulic fluid entry.

- One port for hydraulic fluid.

- Spring or external force for returning the piston.

- Commonly used in lifting applications.

To measure a single-acting cylinder:

- Identify the bore diameter.

- Measure the piston rod diameter.

- Determine the stroke length.

Use a caliper or micrometer for precise measurements. Note the measurements in a table for accuracy.

| Component | Measurement |

|---|---|

| Bore Diameter | Measure the inner diameter of the cylinder. |

| Piston Rod Diameter | Measure the diameter of the piston rod. |

| Stroke Length | Measure the distance the piston travels. |

Double-acting

Double-acting cylinders use hydraulic fluid to move the piston in both directions. They have two ports for hydraulic fluid entry and exit. These cylinders are versatile and used in various applications.

- Two ports for hydraulic fluid.

- Hydraulic fluid moves the piston both ways.

- Commonly used in industrial machinery.

To measure a double-acting cylinder:

- Identify the bore diameter.

- Measure the piston rod diameter.

- Determine the stroke length.

- Note the port locations and sizes.

Ensure precise measurements using appropriate tools. Keep a record of all measurements in a table for reference.

| Component | Measurement |

|---|---|

| Bore Diameter | Measure the inner diameter of the cylinder. |

| Piston Rod Diameter | Measure the diameter of the piston rod. |

| Stroke Length | Measure the distance the piston travels. |

| Port Locations | Identify and measure the port locations and sizes. |

Understanding these cylinder types is key to accurate measurements. Follow these steps and use the right tools for precise results.

Measuring External Dimensions

Measuring the external dimensions of a hydraulic cylinder is crucial. It helps in ensuring compatibility and performance. Two key measurements are the barrel diameter and the rod diameter.

Barrel Diameter

The barrel diameter is the width of the cylinder barrel. This measurement is essential for fitting the cylinder into its housing.

To measure the barrel diameter:

- Use a caliper or a measuring tape.

- Place the tool across the widest part of the barrel.

- Read the measurement and note it down.

Accurate barrel diameter ensures a proper fit and smooth operation.

Rod Diameter

The rod diameter is the width of the rod that extends from the cylinder. Accurate measurement of this dimension is crucial for fitting and functionality.

To measure the rod diameter:

- Use a caliper or a measuring tape.

- Place the tool across the widest part of the rod.

- Take the measurement and record it.

Proper rod diameter ensures the rod moves smoothly within the cylinder.

Determining Stroke Length

Measuring the stroke length of a hydraulic cylinder is crucial. It determines how far the piston can travel inside the cylinder. Knowing this measurement helps in selecting the right cylinder for your application.

Extended Length

The extended length is the measurement from the base of the cylinder to the end of the rod when fully extended. Follow these steps to measure it:

- Fully extend the hydraulic cylinder.

- Use a tape measure to measure from the base to the rod’s end.

- Record this measurement as the extended length.

This length is essential for understanding the maximum reach of the cylinder.

Compressed Length

The compressed length is the measurement from the base of the cylinder to the end of the rod when fully retracted. Follow these steps to measure it:

- Fully retract the hydraulic cylinder.

- Use a tape measure to measure from the base to the rod’s end.

- Record this measurement as the compressed length.

This length is crucial for understanding the minimum length of the cylinder.

| Measurement | Steps |

|---|---|

| Extended Length |

|

| Compressed Length |

|

Understanding both extended and compressed lengths helps in selecting the right hydraulic cylinder.

Assessing Internal Specifications

Measure of a hydraulic cylinder involves assessing internal specifications. This ensures the cylinder performs optimally. Two key internal specifications are the bore size and rod thickness. These measurements help in understanding the cylinder’s capacity and performance.

Bore Size

The bore size is the diameter of the cylinder’s internal chamber. This measurement impacts the cylinder’s force output. Use a caliper to measure the bore size accurately.

To measure:

- Extend the cylinder fully.

- Remove the piston rod.

- Insert the caliper inside the cylinder.

- Read the measurement in millimeters or inches.

A larger bore size means more force. Therefore, knowing the bore size helps in selecting the right cylinder for your needs.

Rod Thickness

The rod thickness is the diameter of the piston rod. This affects the cylinder’s load capacity and stability. A thicker rod can handle more load.

To measure:

- Extend the piston rod fully.

- Use a caliper to measure the rod’s diameter.

- Take multiple measurements for accuracy.

Record the average measurement. This ensures you have the correct rod thickness.

A table can help in understanding the relationship between rod thickness and load capacity:

| Rod Thickness (mm) | Load Capacity (kg) |

|---|---|

| 20 | 500 |

| 25 | 750 |

| 30 | 1000 |

Calculating Retracted And Extended Lengths

Measuring a hydraulic cylinder’s retracted and extended lengths is important. These measurements help ensure the cylinder fits and functions well. Accurate measurements can prevent equipment failure.

Using Formulas

To calculate the retracted length, use this formula:

Retracted Length = Cylinder Body Length + Rod Length

For the extended length, use this formula:

Extended Length = Retracted Length + Stroke Length

These formulas give you precise measurements. Make sure to measure each part correctly.

Practical Tips

- Use a tape measure for better accuracy.

- Check the manufacturer’s manual for exact specifications.

- Ensure the hydraulic cylinder is fully retracted before measuring.

- Record measurements carefully to avoid errors.

| Part | Measurement |

|---|---|

| Cylinder Body | Measure from end to end |

| Rod Length | Measure the rod only |

| Stroke Length | Measure the extension distance |

Using these tips and formulas will help you measure accurately. Accurate measurements ensure the hydraulic cylinder fits and works well. Avoid guessing to prevent problems.

Recording And Interpreting Data

Recording and interpreting data is crucial to measure a hydraulic cylinder. Accurate data ensures proper functionality and longevity of the cylinder. This section will guide you through the process with ease.

Accuracy Considerations

Accuracy is paramount in recording data. Use precise instruments to measure the hydraulic cylinder. Calipers and micrometers are recommended tools. Ensure all tools are calibrated before use.

- Calipers – Ideal for measuring internal and external diameters.

- Micrometers – Best for precise measurements of smaller components.

Document readings meticulously. Double-check all measurements to avoid errors. Record measurements in a consistent unit system. Consistency reduces confusion and errors.

Data Usage

Interpreting data correctly is essential. Use recorded data to assess the cylinder’s condition. Compare current measurements with manufacturer specifications.

| Measurement | Recorded Value | Specification |

|---|---|---|

| Rod Diameter | 25mm | 25mm |

| Bore Diameter | 50mm | 50mm |

- Measure the rod diameter.

- Measure the bore diameter.

- Document all values accurately.

Analyze deviations from specifications. A significant deviation may indicate wear or damage. Regular data recording helps in preventive maintenance.

Maintenance Insights

Keeping your hydraulic cylinder in top shape is essential for its longevity. Regular maintenance and inspections ensure that the cylinder performs optimally. Below are some important maintenance insights to help you keep your hydraulic cylinder in perfect working condition.

Regular Inspection

Conducting regular inspections is the first step in maintaining your hydraulic cylinder. Check for any visible signs of damage or wear.

- Examine the cylinder body for any dents or cracks.

- Inspect the rod for any scratches or bends.

- Ensure all seals are intact and free of leaks.

Regular inspections help you catch potential issues early, preventing costly repairs.

Wear And Tear Indicators

Recognizing wear and tear indicators can save you from major breakdowns. Here are some common signs to watch for:

| Indicator | Description |

|---|---|

| Oil Leaks | Oil around seals or connections indicates a problem. |

| Slow Operation | If the cylinder moves slowly, it may need attention. |

| Unusual Noises | Grinding or squeaking sounds signal wear. |

| Overheating | Excessive heat can point to internal issues. |

Address these indicators promptly to maintain your cylinder’s efficiency.

Troubleshooting Common Measurement Errors

Measuring a hydraulic cylinder can be tricky. Many people make common mistakes. These errors can lead to incorrect measurements. Understanding these errors can help you avoid them. Let’s explore some common issues and how to fix them.

Misalignment Issues

Misalignment can cause inaccurate measurements. Always align the cylinder properly. Here’s how:

- Place the cylinder on a flat surface.

- Ensure both ends are level.

- Use a straight edge to check alignment.

If the cylinder is not aligned, your measurements will be off. Take your time to align it correctly.

Incorrect Tool Use

Using the wrong tool can also cause errors. Always use the right tools:

| Measurement Type | Recommended Tool |

|---|---|

| Length | Measuring Tape |

| Diameter | Caliper |

Measuring tape is best for length. Calipers are best for diameter. Using the wrong tool can lead to mistakes. Make sure to pick the right one.

Check your tools regularly. Worn-out tools can give wrong readings. Replace them if needed.

What Tools Are Needed To Measure A Hydraulic Cylinder?

To measure a hydraulic cylinder, you’ll need a caliper, a tape measure, and a ruler. These tools help in measuring the bore diameter, rod diameter, and stroke length accurately.

How Do You Measure The Stroke Of A Hydraulic Cylinder?

Measure the stroke by extending the cylinder fully. Then, measure from the base to the end of the rod. This distance is the stroke length.

What Is The Bore Diameter Of A Hydraulic Cylinder?

The bore diameter is the internal diameter of the cylinder tube. Measure it using a caliper for precise accuracy.

Why Is Rod Diameter Important In Hydraulic Cylinders?

Rod diameter is crucial for the cylinder’s strength and durability. Measure it using a caliper to ensure proper fit and function.

Conclusion

Accurately measuring a hydraulic cylinder is crucial for proper maintenance and repair. By following the steps outlined, you can ensure precise measurements. This helps in selecting the right replacement parts and maintaining system efficiency. Always double-check your measurements to avoid potential issues.

A well-measured cylinder ensures better performance and longevity.