How to Check Pushrod Length With Hydraulic Lifters? Quick Guide

To check pushrod length with hydraulic lifters, use an adjustable pushrod tool and a checking spring. Measure for proper valve train geometry.

Correct pushrod length is vital for engine performance and longevity. Accurate measurements ensure proper valve train geometry, reducing wear and improving efficiency. An adjustable pushrod tool and checking spring help you determine the ideal pushrod length. This process is crucial for custom engine builds or replacing components in high-performance engines.

By ensuring the correct length, you avoid potential issues such as improper valve seating, noisy operation, and premature wear. Proper pushrod length contributes to optimal engine function and reliability. Follow these steps to maintain engine integrity and performance.

Introduction To Pushrod Length Importance

The correct pushrod length is crucial for engine performance. It ensures proper strong valve operation and prevents engine damage. Understanding pushrod length helps maintain your engine’s health.

Role Of Pushrods In Engine Performance

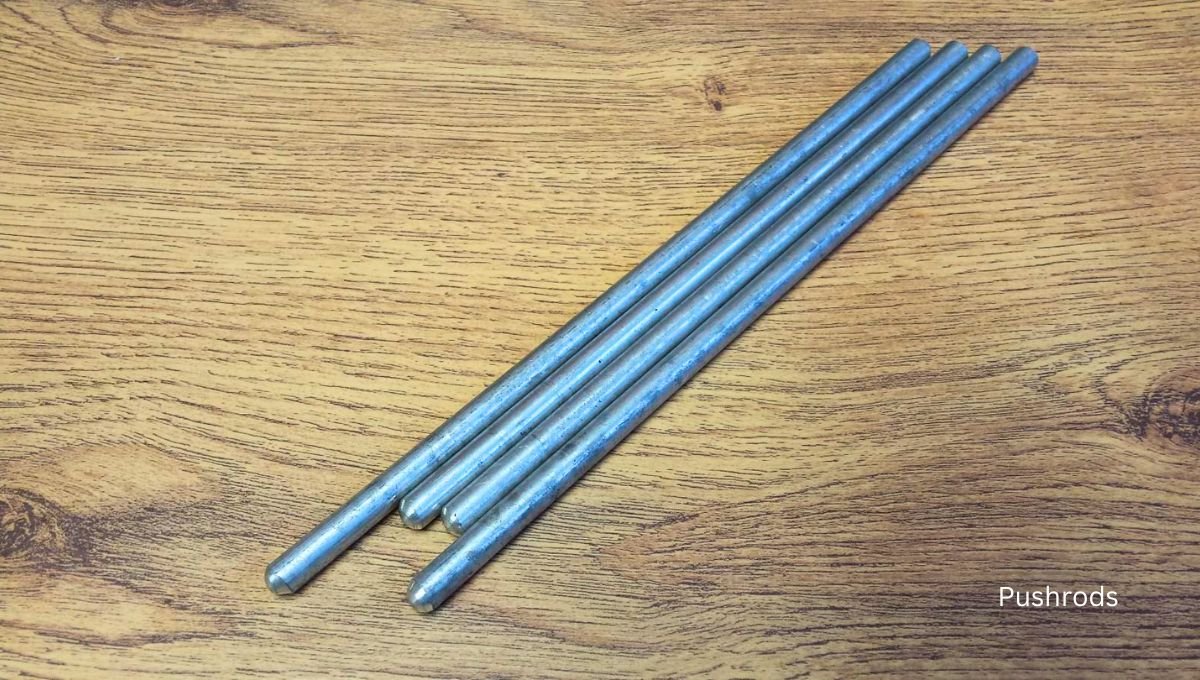

Pushrods are vital in internal combustion engines. They transfer motion from the camshaft to the valves. This motion opens and closes the valves at the right time. The correct pushrod length ensures smooth engine operation.

- Transmits camshaft motion

- Ensures timely valve operation

- Maintains engine efficiency

Consequences Of Incorrect Pushrod Length

Incorrect pushrod length can cause several issues. It can lead to poor engine performance and damage. Below are some consequences:

| Incorrect Length | Potential Issue |

|---|---|

| Too Short | Valves may not open fully |

| Too Long | Valves may not close properly |

- Increased wear on engine parts

- Reduced fuel efficiency

- Poor overall engine performance

Basics Of Hydraulic Lifters

The basics of hydraulic lifters is essential for checking pushrod length. Hydraulic lifters are crucial components in an engine’s valvetrain. They help ensure smooth operation and reduce maintenance needs. Proper functioning of hydraulic lifters can enhance engine performance.

Function Of Hydraulic Lifters

Hydraulic lifters help in maintaining zero valve clearance. They automatically adjust to the expansion and contraction of engine parts. This automatic adjustment reduces wear and tear on the engine. Hydraulic lifters also minimize the noise produced by the engine.

Inside a hydraulic lifter, there is a small piston. This piston is controlled by the oil pressure in the engine. The oil pressure helps the piston to adjust the lifter’s height. This, in turn, helps in maintaining the right valve clearance. Proper valve clearance is vital for optimal engine performance.

Hydraulic Lifters Vs. Solid Lifters

Hydraulic lifters and solid lifters serve similar purposes but function differently. Hydraulic lifters adjust automatically, while solid lifters require manual adjustment. This makes hydraulic lifters more user-friendly.

| Feature | Hydraulic Lifters | Solid Lifters |

|---|---|---|

| Adjustment | Automatic | Manual |

| Maintenance | Low | High |

| Noise Level | Low | High |

| Performance | Stable | High performance |

Hydraulic lifters require less frequent adjustments. Solid lifters offer high-performance but need regular maintenance. Choosing between them depends on your engine requirements and maintenance preferences.

Essential Tools For Measuring Pushrod Length

To check pushrod length with hydraulic lifters is essential for proper engine performance. Using the right tools ensures precise measurements. This guide covers the essential tools to check pushrod length with hydraulic lifters.

Pushrod Length Checker

A pushrod length checker is a must-have tool. It helps you determine the correct length for your engine. This tool is adjustable and fits different engine types.

- Adjustable – Fits various engine sizes.

- Easy to Use – Simple design ensures quick measurements.

- Accurate – Provides precise measurements for better engine performance.

Using a pushrod length checker ensures that your engine runs smoothly.

Micrometer And Calipers

A micrometer and calipers are essential for accurate measurements. These tools measure the pushrod length to a high degree of precision.

| Tool | Usage |

|---|---|

| Micrometer | Measures small lengths with high precision. |

| Calipers | Measures the diameter and length of pushrods. |

Ensure you have both tools for the most accurate results. A micrometer can measure down to thousandths of an inch. Calipers are great for quick and easy measurements.

Use these tools together for the best accuracy. This combination ensures your engine runs at its best.

Preparation For Measurement

Before checking pushrod length with hydraulic lifters, proper preparation is crucial. This ensures accurate measurements and prevents damage to engine components. Follow these steps to prepare for the measurement process.

Engine Disassembly Tips

- Ensure the engine is cool to avoid burns.

- Disconnect the battery to prevent accidental starts.

- Drain the engine oil to avoid spills.

- Remove the valve covers to access the lifters.

- Label each part during disassembly to ease reassembly.

Safety Precautions

Safety should always be a priority. Follow these precautions to protect yourself and your equipment:

- Wear safety goggles to protect your eyes from debris.

- Use gloves to protect your hands from sharp edges.

- Ensure proper ventilation to avoid inhaling fumes.

- Keep a fire extinguisher nearby in case of emergencies.

- Work in a well-lit area to see clearly.

| Task | Tools Needed |

|---|---|

| Disconnect battery | Wrench |

| Drain engine oil | Drain pan, wrench |

| Remove valve covers | Screwdriver, socket set |

Step-by-step Measurement Procedure

Checking the pushrod length with hydraulic lifters is crucial. Accurate measurements ensure optimal engine performance. Follow these steps for precise results.

Setting Up The Checker

First, gather your tools. You need a pushrod length checker, a wrench set, and your hydraulic lifters. Place the engine in a location with good lighting.

Next, remove the existing pushrod. Install the adjustable pushrod length checker in its place. Ensure it fits snugly.

Turn the engine by hand until the lifter is on the base circle of the camshaft. This is the point where the lifter is at its lowest position.

Adjusting For Zero Lash

Zero lash is when there is no gap between the lifter and the pushrod. To achieve this, carefully turn the adjustable pushrod checker.

Rotate the pushrod checker until you feel resistance. This indicates zero lash. Ensure there is no play between the components.

Use a feeler gauge if needed to double-check the zero lash. Precision is vital at this step.

Reading The Measurement

With zero lash set, remove the pushrod checker carefully. Measure its length using a caliper or a micrometer.

Record the measurement. Compare it with the manufacturer’s specifications for your engine.

If the measurement matches, your pushrod length is correct. If not, you may need a different pushrod length.

Repeat the process for each pushrod to ensure consistency. Always double-check your measurements for accuracy.

Analyzing Measurement Results

Analyzing the measurement results is crucial in ensuring the correct pushrod length. This step helps in fine-tuning engine performance. Incorrect pushrod length can lead to engine issues. Let’s dive into interpreting these results.

Interpreting Length Variations

After measuring, you may find length variations. These variations occur due to different factors. Hydraulic lifters can compress under load, affecting measurements. Use a pushrod length checker tool for accuracy.

- Check for consistent readings across all pushrods.

- Note any significant differences in length.

- Record the lengths for reference.

If variations are minor, they might not affect performance. Major differences indicate a need for adjustment. Consistent lengths ensure engine components work harmoniously.

When To Adjust Pushrod Length

Adjust pushrod length if you notice significant variations. This adjustment ensures optimal engine function. Here are signs you need to adjust:

- Engine noise or tapping sounds.

- Inconsistent valve operation.

- Poor engine performance.

Use an adjustable pushrod tool to find the correct length. Recheck measurements after adjustment. This guarantees accuracy and optimal engine performance.

Selecting The Correct Pushrods

Choosing the right pushrods ensures your engine runs smoothly. Correct pushrods prevent damage and ensure optimal performance. This section explores key aspects to help you select the best pushrods for hydraulic lifters.

Material And Design Considerations

Pushrods come in various materials and designs. Understanding these differences is crucial. Common materials include steel, chrome-moly, and aluminum. Each material has unique benefits and drawbacks.

| Material | Benefits | Drawbacks |

|---|---|---|

| Steel | Durable, Cost-effective | Heavier |

| Chrome-Moly | High strength, Lightweight | More expensive |

| Aluminum | Very lightweight, High RPMs | Less durable |

Steel pushrods are durable but heavier. Chrome-moly offers high strength with less weight but costs more. Aluminum is very light and ideal for high RPMs but is less durable.

Sourcing Quality Pushrods

High-quality pushrods ensure reliable engine performance. Look for reputable brands and check reviews. Quality pushrods often have better materials and precise manufacturing.

- Check for brands with good reviews

- Ensure proper material selection

- Verify manufacturing precision

Reputable brands provide assurance of quality. Proper material selection ensures compatibility with your engine. Manufacturing precision guarantees reliable performance.

Always measure pushrod length accurately. Correct length is vital for engine efficiency. Use a pushrod length checker for precise measurements.

Troubleshooting Common Issues

To check the pushrod length with hydraulic lifters can sometimes be tricky. Various problems may arise during the process. This section will help you troubleshoot common issues. You will learn how to deal with measurement errors and find solutions for hydraulic lifter problems.

Dealing With Measurement Errors

Measurement errors are common in pushrod length checking. Here are some tips to avoid them:

- Use a precise tool: Invest in a high-quality pushrod length checker.

- Ensure zero lash: Confirm there’s no play in the valvetrain.

- Repeat measurements: Take multiple readings for accuracy.

Using a table can help you track measurements:

| Attempt | Measurement (inches) |

|---|---|

| 1 | 7.250 |

| 2 | 7.255 |

| 3 | 7.250 |

Solutions For Hydraulic Lifter Problems

Hydraulic lifters can cause issues during pushrod length measurement. Here’s how to solve them:

- Ensure proper lifter preload: Incorrect preload affects measurement.

- Check for lifter bleed-down: A faulty lifter might bleed down too quickly.

- Inspect for air in lifter: Air bubbles can cause inaccurate readings.

Follow these steps to maintain accurate pushrod length measurements and avoid common issues.

Final Assembly And Engine Testing

The final assembly and engine testing are crucial steps in checking pushrod length with hydraulic lifters. These steps ensure everything works smoothly and efficiently. Properly reassembling the valve train and conducting a test run are essential tasks. This guide will help you complete these tasks successfully.

Reassembling The Valve Train

Begin by reassembling the valve train with precision. Ensure all components are clean and free of debris. Use a clean cloth to wipe each part thoroughly. Proper assembly ensures optimal engine performance.

- Install the pushrods carefully.

- Position the rocker arms correctly.

- Tighten the rocker arm nuts to the recommended torque.

Next, adjust the valve lash according to the manufacturer’s specifications. This step is vital for smooth engine operation. Use a feeler gauge to measure the clearance accurately.

Double-check all connections and ensure everything is secure. A loose component can cause significant issues.

Conducting A Test Run

After reassembling the valve train, conduct a test run to verify the adjustments. Start the engine and let it idle for a few minutes. Listen for unusual noises or vibrations.

Monitor the engine’s performance closely. Check for any signs of leaks or irregularities. Use a diagnostic tool to read engine parameters.

- Start the engine and let it warm up.

- Observe the oil pressure gauge.

- Check for smooth operation and stability.

Ensure the engine runs smoothly without any disruptions. If you notice any issues, stop the engine immediately and recheck the assembly.

Finally, take the vehicle for a short drive. This helps to validate the adjustments under real-world conditions. Pay attention to the engine’s response and performance.

After completing the test run, perform a final inspection. Check all components again to ensure everything is in place. This step confirms that the pushrod length is correct and the hydraulic lifters are functioning properly.

Maintenance Tips For Longevity

Maintaining your hydraulic lifters and pushrods can extend their life. Follow these tips to ensure they stay in top condition.

Regular Inspection Routines

Regularly inspect your pushrods and hydraulic lifters. Look for signs of wear, such as scratches or dents.

Use a caliper to measure the pushrod length. Compare it with the manufacturer’s specifications.

If the pushrod length is off, adjust or replace it. This ensures optimal performance and longevity.

Lubrication And Care Advice

Always keep your hydraulic lifters well-lubricated. Use high-quality engine oil for the best results.

Lubrication reduces friction, preventing excessive wear and tear. It also keeps the pushrods and lifters running smoothly.

Clean the pushrods and lifters during oil changes. Remove any dirt or debris that could cause damage.

| Maintenance Task | Frequency |

|---|---|

| Inspect Pushrods | Every 3 months |

| Measure Pushrod Length | Every 6 months |

| Lubricate Lifters | During every oil change |

| Clean Components | During every oil change |

What Tools Are Needed To Check Pushrod Length?

You will need a pushrod length checker, hydraulic lifters, and a feeler gauge. These tools help ensure accurate measurements.

Why Is Pushrod Length Important?

Correct pushrod length ensures proper valve timing and engine performance. It prevents premature wear and potential engine damage.

Can I Check Pushrod Length With Hydraulic Lifters Installed?

Yes, you can. Ensure the lifters are fully collapsed for accurate measurements. This mimics the lifter’s operating condition.

How Do I Measure Pushrod Length?

Install the pushrod length checker, then rotate the engine by hand. Measure the pushrod length once the lifter is fully compressed.

Conclusion

Checking pushrod length with hydraulic lifters is crucial for engine performance. Follow the steps outlined to ensure accuracy. This simple yet vital task can prevent engine damage. Proper pushrod length ensures your engine runs smoothly and efficiently. Keep your vehicle in top shape by regularly checking and adjusting pushrod lengths.