How to Check Hydraulic Fluid Level? Quick & Easy Guide

To check the hydraulic fluid level, locate the reservoir and read the dipstick or sight glass. Ensure the machine is on level ground.

Proper hydraulic fluid maintenance is crucial for the efficiency and longevity of hydraulic systems. Regularly checking the hydraulic fluid level helps prevent potential damage and costly repairs. Hydraulic systems rely on fluid to transfer power, so maintaining the correct fluid level is essential.

Low fluid levels can lead to overheating and component wear. Always ensure the equipment is on level ground before checking. Clean the area around the reservoir to prevent contamination. Using the dipstick or sight glass, verify the fluid level matches the manufacturer’s recommended range. Regular checks ensure your hydraulic system operates smoothly and efficiently.

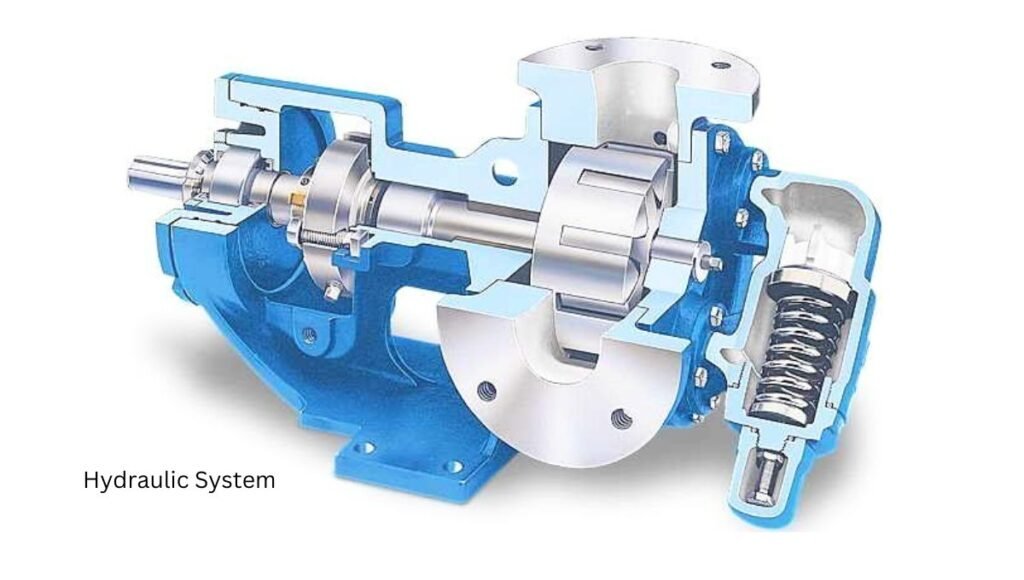

Introduction To Hydraulic Systems

Hydraulic systems play a crucial role in many machines. They use fluid power to perform heavy tasks with ease. Understanding these systems is key to maintaining them.

Essential Role Of Hydraulic Fluid

Hydraulic fluid is like the lifeblood of a hydraulic system. It transfers power and lubricates moving parts. This fluid also helps in cooling the system. Without the right amount, the system can fail.

Consequences Of Improper Fluid Levels

- Increased wear and tear on parts

- Overheating of the system

- Reduced efficiency and power

- Potential system failure

| Issue | Consequence |

|---|---|

| Low Fluid | Increased friction and overheating |

| High Fluid | Spill risks and reduced efficiency |

Safety First: Preparing To Check Fluid Levels

Before checking hydraulic fluid levels, ensure safety first. Proper preparation prevents accidents. Wear suitable gear and secure machinery.

Personal Protective Equipment

Always wear personal protective equipment (PPE). This includes gloves, goggles, and safety boots. Hydraulic fluid can irritate skin and eyes. PPE keeps you safe from spills and splashes.

- Gloves: Protects your hands from hydraulic fluid.

- Goggles: Shields your eyes from splashes.

- Safety Boots: Prevents foot injuries from heavy machinery.

Securing The Machinery

Always secure the machinery before checking fluid levels. Turn off the engine and remove the key. This prevents accidental start-ups.

- Turn Off: Switch off the engine completely.

- Remove Key: Take out the key to avoid accidental starts.

- Lockout/Tagout: Use lockout/tagout procedures if available.

Ensure the machinery is on stable ground. This avoids tipping over during checks. Safety is key before checking hydraulic fluid.

Identifying The Hydraulic Reservoir

Checking the hydraulic fluid level is essential for machine maintenance. The first step is identifying the hydraulic reservoir. This guide will help you locate and understand the reservoir in different machines.

Locating The Reservoir In Different Machines

The hydraulic reservoir can be in various places, depending on the machine type.

- Excavators: The reservoir is usually near the engine compartment.

- Tractors: Look under the seat or near the rear axle.

- Forklifts: It’s often found behind the driver’s seat or near the mast.

- Backhoes: Typically, it’s located near the rear wheels or under the hood.

Understanding Reservoir Types

Hydraulic reservoirs come in different types. Knowing these helps in identifying and maintaining them.

- Metal Tanks: Common in heavy machinery. These are durable and easy to spot.

- Plastic Tanks: Found in smaller machines. They are lightweight and often translucent.

- Integrated Reservoirs: These are built into the machine’s frame. They are harder to access but save space.

Refer to the machine’s manual for precise locations. Regularly checking the hydraulic fluid ensures the machine runs smoothly.

Tools You’ll Need

Checking the hydraulic fluid level is crucial for your machinery’s performance. Using the right tools ensures accuracy and safety. In this section, we will cover the essential tools and alternative methods you can use.

Choosing The Right Equipment

To check the hydraulic fluid level, you will need specific tools. Here is a list of the essential items:

- Dipstick: Measures the fluid level accurately.

- Clean Rag: Wipes off excess fluid for a clear reading.

- Flashlight: Helps you see the fluid level in low light.

- Gloves: Protects your hands from oil and dirt.

Ensure your dipstick is clean before using it. A dirty dipstick can give you a false reading. Always use a clean rag to wipe it off before inserting it into the hydraulic fluid reservoir.

Alternative Methods Without Special Tools

If you don’t have a dipstick, you can still check the fluid level. Here are some alternative methods:

- Visual Inspection: Open the reservoir cap and look inside.

- Use a Stick: Find a clean stick and dip it into the fluid.

- Check the Fluid Indicator: Some machines have built-in indicators.

For a visual inspection, make sure the machinery is on a level surface. Use a flashlight for better visibility. When using a stick, ensure it is clean to avoid contaminating the fluid.

Built-in indicators are often marked with minimum and maximum levels. Check these markings to ensure the fluid is within the safe range.

Steps To Check Hydraulic Fluid Level

Knowing how to check hydraulic fluid level is essential. Proper fluid levels ensure the system runs smoothly. Follow these steps for accurate readings and maintenance.

Cleaning The Area Around Dipstick Or Sight Glass

First, locate the dipstick or sight glass. The dipstick is usually near the hydraulic reservoir. The sight glass is on the side of the tank.

Next, clean the area around the dipstick or sight glass. Use a clean rag to wipe away dirt and debris. This prevents contaminants from entering the hydraulic system.

Check that the area is completely clean. Any dirt can cause serious issues. Ensure there is no grime left before proceeding.

Reading The Fluid Level Correctly

Remove the dipstick carefully. Wipe it clean with a rag. Insert the dipstick back into the reservoir fully.

Remove the dipstick again and check the fluid level. The fluid should be within the marked range. If using a sight glass, the fluid should be visible within the indicators.

Top up the hydraulic fluid if the level is low. Make sure to use the recommended type of fluid. Do not overfill the reservoir.

Replace the dipstick or close the sight glass. Ensure it is securely fastened. This helps maintain system pressure and prevent leaks.

| Step | Action |

|---|---|

| 1 | Locate dipstick or sight glass |

| 2 | Clean area around dipstick or sight glass |

| 3 | Remove and clean dipstick |

| 4 | Reinsert and remove dipstick to check level |

| 5 | Top up fluid if needed |

| 6 | Secure dipstick or sight glass |

Interpreting Fluid Level Indicators

Checking your hydraulic fluid level is crucial for system health. Understanding fluid level indicators helps you maintain optimal performance. This section will guide you through the key aspects of interpreting these indicators.

What The Marks Mean

Hydraulic systems often have transparent reservoirs with marked indicators. These markers show “Full” and “Low” levels. Knowing what these marks mean is essential for accurate readings.

- Full: Indicates the reservoir is at its optimal capacity.

- Low: Suggests the fluid is below the safe level.

Always check the fluid level when the system is off. This ensures an accurate reading. If the fluid is below the “Low” mark, you need to add more.

When To Top Off Vs. When To Change Fluid

Knowing when to top off or change the fluid can extend the system’s life. Here’s how to decide:

| Indicator | Action Needed |

|---|---|

| Fluid is clear and near Full mark | Top off the fluid |

| Fluid is dark or contains debris | Change the fluid |

| Frequent low levels | Check for leaks |

Always use the manufacturer’s recommended fluid. This ensures compatibility and efficiency. Remember, topping off is a temporary fix. Changing fluid ensures long-term performance.

Troubleshooting Common Issues

Hydraulic systems can sometimes face problems. Regular checks help maintain efficiency. Knowing the signs can prevent major issues. Here, we explore some common problems. Learn how to tackle them effectively.

Dealing With A Cloudy Or Milky Reservoir

A cloudy or milky reservoir indicates water contamination. Water in the hydraulic fluid can cause damage. Follow these steps to handle this issue:

- Turn off the hydraulic system to prevent further damage.

- Drain the contaminated fluid from the reservoir.

- Inspect the system for any leaks or entry points for water.

- Replace the fluid with fresh, clean hydraulic fluid.

- Monitor the system for any recurring issues.

Keeping the fluid clean ensures a longer lifespan for your hydraulic system.

Responding To Low Fluid Levels

Low fluid levels can cause the system to malfunction. This can lead to severe damage. Address this problem promptly:

- Check the fluid levels using the dipstick or sight gauge.

- Top up with the correct type of hydraulic fluid if levels are low.

- Inspect for any visible leaks in the system.

- Tighten any loose fittings to prevent further leaks.

- Monitor the levels regularly to ensure they stay within the safe range.

Maintaining proper fluid levels is crucial for optimal performance.

Maintaining Optimal Fluid Levels

To keep your hydraulic systems running smoothly, maintaining optimal fluid levels is crucial. Proper fluid levels ensure efficient operation and prevent damage. Regular checks and using the right hydraulic fluid are essential steps.

Best Practices For Regular Checks

Perform regular checks to monitor hydraulic fluid levels. Follow these best practices:

- Check the fluid level before starting the machine.

- Ensure the machine is on a flat surface.

- Use the dipstick or sight glass to check levels.

- Top off the fluid if it’s below the recommended level.

- Keep the fluid reservoir clean to avoid contamination.

Choosing The Right Hydraulic Fluid

Selecting the right hydraulic fluid is vital for system efficiency. Consider these factors:

- Check the manufacturer’s recommendations.

- Choose fluid based on operating temperature range.

- Ensure compatibility with system components.

- Opt for fluids with anti-wear additives.

- Avoid mixing different types of fluids.

Below is a table showing different types of hydraulic fluids and their uses:

| Type of Hydraulic Fluid | Recommended Use |

|---|---|

| Mineral Oil | General-purpose hydraulic systems |

| Water-based Fluids | Fire-resistant applications |

| Synthetic Fluids | High-temperature environments |

By following these practices, you ensure your hydraulic system operates efficiently. Regular checks and using the correct fluid type prevent issues. Keep your machinery in top condition with these simple steps.

Ensuring Hydraulic System Health

Maintaining hydraulic systems is crucial for smooth machinery operations. Checking the fluid level is a key step. Regular checks prevent machinery breakdowns and ensure optimal performance. This section wraps up our discussion and highlights the importance of this maintenance task.

Summarizing Key Takeaways

- Regular checks: Frequent fluid level inspections are essential.

- Proper tools: Use the correct tools for accurate measurements.

- Clean environment: Ensure the area around the reservoir is clean.

- Correct fluid type: Always use the recommended hydraulic fluid.

Importance Of Regular Maintenance

Regular maintenance of hydraulic systems extends machinery life. It prevents unexpected failures and costly repairs. Keeping fluid levels in check is a small task with big benefits.

Proper fluid levels ensure that the system operates efficiently. It also helps in identifying potential issues early. This proactive approach saves time and money.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Check fluid level | Weekly | Prevents breakdowns |

| Inspect for leaks | Monthly | Avoids fluid loss |

| Replace filters | Quarterly | Maintains fluid purity |

Regular checks and maintenance lead to a healthy hydraulic system. This ensures that the machinery performs at its best.

How Do You Check Hydraulic Fluid Level?

To check hydraulic fluid level, locate the reservoir. Remove the dipstick or cap. Ensure the fluid level is between the minimum and maximum marks.

Why Is Checking Hydraulic Fluid Important?

Checking hydraulic fluid is crucial for system performance. Low levels can cause malfunction or damage. Regular checks ensure optimal operation and longevity.

When Should You Check Hydraulic Fluid?

Check hydraulic fluid before starting any hydraulic machinery. Regularly inspect based on manufacturer recommendations, usually every few months or after heavy use.

What Tools Are Needed To Check Hydraulic Fluid?

You’ll need a clean cloth, the correct dipstick, and possibly a flashlight. These tools help you accurately read the fluid level.

Conclusion

Regularly checking your hydraulic fluid level is essential. It ensures your machinery runs smoothly and efficiently. Follow the steps outlined in this guide to maintain optimal performance. Proper fluid levels prevent damage and extend the lifespan of your equipment. Stay proactive with maintenance for better reliability and safety.