How To Bleed A Hydraulic Cylinder Without Bleeder Valve? Explore

To bleed a hydraulic cylinder without a bleeder valve, cycle the cylinder fully to expel trapped air. Repeat the process until smooth operation is achieved.

Bleeding a hydraulic cylinder without a bleeder valve might seem challenging but is quite doable with the right method. The process involves cycling the cylinder through its full range of motion multiple times. This helps push any trapped air out of the system, ensuring smooth and efficient operation.

Regular maintenance of hydraulic cylinders is crucial to prevent air entrapment and maintain optimal performance. Understanding how to properly bleed a hydraulic cylinder can save time, effort, and avoid potential mechanical issues. This guide provides simple steps to effectively remove air from your hydraulic system.

Required Tools And Materials

Bleeding a hydraulic cylinder without a bleeder valve requires specific tools and safety gear. Having the right materials ensures the job is done smoothly and safely.

Essential Tools

- Hydraulic fluid: The right type of fluid is crucial.

- Wrenches: Various sizes to fit different bolts.

- Screwdrivers: Both flathead and Phillips.

- Funnel: Helps in pouring hydraulic fluid without spills.

- Drain pan: Catches old fluid to keep the area clean.

Safety Gear

| Safety Item | Purpose |

|---|---|

| Safety gloves | Protects hands from chemicals and injuries. |

| Safety goggles | Shields eyes from fluid splashes. |

| Work apron | Keeps clothes free from stains. |

| Non-slip shoes | Prevents accidents on slippery surfaces. |

Ensure all tools and safety gear are within reach. This preparation saves time and enhances safety.

Preparation Steps

Bleeding a hydraulic cylinder without a bleeder valve requires careful preparation. Proper steps ensure safety and efficiency. Here’s a detailed guide on the preparation steps you need.

Securing The Work Area

Before starting, ensure the work area is safe and organized. Remove any unnecessary items. Clear the area of obstacles to avoid tripping.

- Wear protective gear: gloves, goggles, and sturdy shoes.

- Ensure proper lighting in the work area.

- Use barriers to keep unauthorized persons out.

- Have a first-aid kit nearby for emergencies.

Positioning The Hydraulic Cylinder

Positioning the hydraulic cylinder correctly is crucial. It ensures proper bleeding and safety. Follow these steps:

- Place the cylinder on a stable surface. Avoid wobbly tables or uneven ground.

- Ensure the cylinder is fully extended. This allows air to escape more easily.

- Secure the cylinder with clamps or straps. This prevents movement during the process.

- Check for leaks or damage. Inspect the cylinder thoroughly before proceeding.

Following these preparation steps ensures a smooth and safe bleeding process for your hydraulic cylinder.

Manual Bleeding Method

Bleeding a hydraulic cylinder without a bleeder valve can seem tricky. The manual bleeding method is a practical solution. This method ensures the cylinder functions smoothly. Follow these steps carefully to achieve the best results.

Step-by-step Process

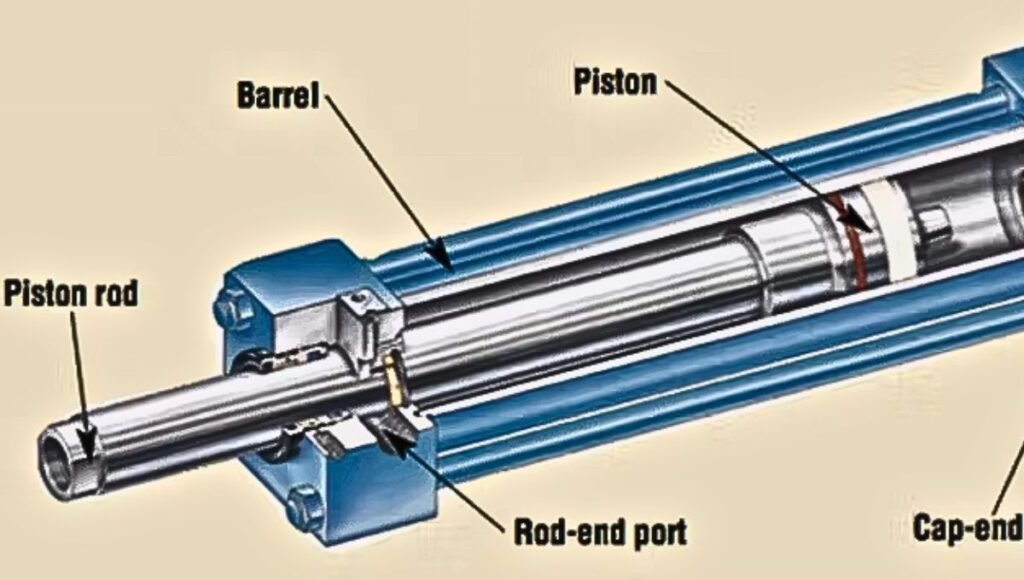

- Raise the Cylinder: Elevate the hydraulic cylinder to allow air to rise.

- Extend the Cylinder: Fully extend the piston rod.

- Open the Hydraulic Lines: Loosen the fittings to release trapped air.

- Operate the Cylinder: Move the piston rod back and forth several times.

- Check for Air Bubbles: Observe the hydraulic fluid for air bubbles.

- Tighten the Fittings: Once air is expelled, tighten the hydraulic lines.

- Test the Cylinder: Operate the cylinder to ensure smooth movement.

Tips For Effective Bleeding

- Use Clear Hoses: Clear hoses help you see air bubbles easily.

- Work in a Clean Area: Dirt can contaminate the hydraulic system.

- Maintain Fluid Levels: Ensure hydraulic fluid is at the correct level.

- Repeat if Necessary: Repeat the process if air remains in the system.

- Use Proper Tools: Use wrenches and pliers to handle fittings securely.

Following these steps ensures your hydraulic cylinder works efficiently. Regular maintenance is key to avoiding air in the system.

Using The Cylinder’s Motion

Bleeding a hydraulic cylinder without a bleeder valve can be tricky. Using the cylinder’s motion is a practical method. This method helps in removing trapped air efficiently. Follow these steps for a smooth process.

Extending And Retracting The Cylinder

Start by fully extending the cylinder. Ensure the hydraulic system is running. Slowly extend the cylinder to its maximum length. This pushes out air trapped inside.

Next, retract the cylinder completely. Repeat this process several times. This helps in moving the air towards the reservoir. Ensure the cylinder moves smoothly during this process.

| Step | Action |

|---|---|

| 1 | Extend the cylinder fully |

| 2 | Retract the cylinder completely |

| 3 | Repeat the process |

Monitoring Air Release

Keep an eye on the hydraulic fluid. Bubbles indicate air being released. Check the fluid reservoir frequently. Make sure it is not running low.

Listen for hissing sounds. These sounds mean air is escaping. Continue the extending and retracting steps until no air remains.

- Check the fluid level

- Watch for air bubbles

- Listen for hissing sounds

- Repeat the process until smooth operation

Alternative Methods

To bleed a hydraulic cylinder without a bleeder valve can be tricky. Thankfully, there are alternative methods that can help. These methods ensure the smooth operation of your hydraulic system.

Using Auxiliary Equipment

One effective way is by using auxiliary equipment. This method involves tools like vacuum pumps. A vacuum pump helps in removing air bubbles from the hydraulic system.

Steps to use a vacuum pump:

- Attach the vacuum pump to the hydraulic system.

- Turn on the pump to create a vacuum.

- Observe as air bubbles get sucked out.

- Turn off the pump once all bubbles are removed.

Another tool that can be useful is a hydraulic jack. It helps in raising the cylinder to let air escape naturally. Ensure you follow safety procedures while using these tools.

Professional Assistance

If you lack the necessary tools, you can seek professional assistance. Experts have the right equipment and experience. They can quickly identify and fix air lock issues.

Benefits of professional help:

- Quick and efficient service.

- Use of specialized tools.

- Experience in handling complex issues.

Consider professional help if you face persistent issues. Their expertise can save you time and effort.

Using these alternative methods ensures your hydraulic system runs smoothly. Always prioritize safety and efficiency.

Common Mistakes To Avoid

To bleed a hydraulic cylinder without a bleeder valve can be tricky. To ensure success, it’s crucial to know what mistakes to avoid. Here are some common errors you should steer clear of.

Overlooking Safety Precautions

Safety should always come first. Many people forget to wear protective gear. Always wear gloves and safety glasses to protect yourself.

Another common mistake is not securing the hydraulic system. Always make sure the system is stable. Use clamps or braces if necessary.

Improperly disconnecting hydraulic lines can be dangerous. Always release the pressure before disconnecting any lines. This prevents accidents and injuries.

Ignoring Air Pockets

Air pockets can hamper the efficiency of your hydraulic system. Many people ignore this step. Always check for air pockets when bleeding the system.

To remove air pockets, cycle the cylinder multiple times. Extend and retract the cylinder fully. This helps to push out any trapped air. </p

Another tip is to keep the fluid level topped up. Low fluid levels can introduce more air into the system. Always maintain the recommended fluid level.

| Common Mistakes | Solution |

|---|---|

| Not wearing protective gear | Always wear gloves and safety glasses |

| Not securing the hydraulic system | Use clamps or braces |

| Improperly disconnecting lines | Release pressure before disconnecting |

| Ignoring air pockets | Cycle the cylinder multiple times |

| Low fluid levels | Keep fluid level topped up |

Maintenance Tips

Maintaining a hydraulic cylinder without a bleeder valve requires special care. Regular maintenance ensures smooth operation and avoids potential issues. Follow these tips to keep your hydraulic cylinder in top shape.

Regular Inspection

Inspect your hydraulic cylinder regularly. Look for leaks, rust, and wear. Check seals, rods, and connections. Use a flashlight to see inside hard-to-reach areas. Ensure no debris or dirt is present.

- Check for oil leaks around seals.

- Look for rust on the cylinder rod.

- Inspect the connections for tightness.

- Clean any visible dirt or debris.

Proper Storage Practices

Store your hydraulic cylinder correctly to avoid damage. Keep it in a dry, clean place. Avoid areas with high moisture or dirt. Use protective covers if available.

- Store in a dry, clean environment.

- Avoid storing in damp or dusty areas.

- Use protective covers to shield from dirt.

- Keep away from direct sunlight.

Maintenance Frequency

How often you maintain your hydraulic cylinder depends on usage. Heavy usage requires more frequent checks. Light usage means less frequent but still regular inspections.

| Usage Type | Inspection Frequency |

|---|---|

| Heavy Usage | Weekly |

| Moderate Usage | Bi-weekly |

| Light Usage | Monthly |

How Do You Bleed A Hydraulic Cylinder Without A Bleeder Valve?

Bleeding a hydraulic cylinder without a bleeder valve involves extending and retracting the cylinder fully. This process helps to expel any trapped air. Always ensure the hydraulic fluid level is adequate.

What Tools Are Needed To Bleed A Hydraulic Cylinder?

You will need a hydraulic fluid, a clean container, and a wrench. Ensure you have safety gloves and goggles.

Can Trapped Air Damage Hydraulic Cylinders?

Yes, trapped air can cause erratic movements and reduced efficiency. It may also lead to cavitation and damage seals.

How Often Should Hydraulic Cylinders Be Bled?

Hydraulic cylinders should be bled whenever air is suspected in the system. Regular maintenance can prevent air entrapment.

Conclusion

To bleed a hydraulic cylinder without a bleeder valve can seem daunting, but it’s manageable with the right steps. Follow these guidelines carefully to ensure a smooth process. Remember to prioritize safety and double-check all connections. Proper maintenance will extend the lifespan of your hydraulic system, saving you time and money in the long run.