How to Adjust Hydraulic Roller Lifters? Quick Tips

To adjust hydraulic roller lifters, set the engine to Top Dead Center (TDC) and tighten the rocker arms. Ensure zero lash and then add a half-turn.

Hydraulic roller lifters play a crucial role in an engine’s performance. Proper adjustment ensures optimal valve operation and engine efficiency. The process involves positioning the engine at TDC, where the lifters are neither compressing nor extending. Tightening the rocker arms to achieve zero lash, followed by a half-turn, completes the adjustment.

This method prevents excessive wear and maintains smooth engine functioning. Regular maintenance and accurate adjustments can prolong engine life and enhance overall vehicle performance. Understanding the procedure is vital for both novice and experienced mechanics aiming to maintain peak engine health.

Introduction To Hydraulic Roller Lifters

Hydraulic roller lifters are vital parts of modern engines. They help control the engine’s valves. This improves the overall performance of the engine.

Role In Engine Performance

These lifters reduce friction inside the engine. Less friction means the engine runs smoother. This can extend the engine’s life.

Hydraulic roller lifters also improve fuel efficiency. The engine uses fuel more effectively. This saves money on gas.

They also help in reducing engine noise. A quieter engine is more pleasant to drive.

Benefits Of Using Hydraulic Roller Lifters

- Improved Performance: The engine runs more smoothly.

- Increased Durability: They help extend engine life.

- Better Fuel Efficiency: Save money on gas.

- Reduced Noise: Enjoy a quieter engine.

| Benefit | Description |

|---|---|

| Improved Performance | The engine runs more smoothly. |

| Increased Durability | They help extend engine life. |

| Better Fuel Efficiency | Save money on gas. |

| Reduced Noise | Enjoy a quieter engine. |

Tools And Materials Needed

Understanding the tools and materials needed for adjusting hydraulic roller lifters is crucial. Having the right equipment ensures a smooth and efficient process. This guide will help you gather everything you need.

List Of Essential Tools

- Socket Set: Different sizes for various bolts.

- Torque Wrench: Ensures proper tension on bolts.

- Feeler Gauge: Measures the gap between components.

- Valve Spring Compressor: Essential for compressing valve springs.

- Ratchet Wrench: Helps to loosen and tighten bolts.

Additional Materials For Setup

- Engine Oil: Lubricates the lifters and other parts.

- Rags: Used for cleaning and wiping excess oil.

- Service Manual: Provides specific instructions for your engine model.

- Safety Glasses: Protects your eyes from debris.

- Gloves: Protects your hands while working.

Preparation Steps

Proper preparation is crucial before adjusting hydraulic roller lifters. This ensures safety and efficiency. Follow these steps to get ready for the task.

Safety Precautions

Safety should be your top priority. Here are essential safety measures:

- Wear safety goggles to protect your eyes.

- Use gloves to keep your hands safe.

- Ensure the vehicle is parked on a flat surface.

- Disconnect the battery to avoid electrical hazards.

- Keep a fire extinguisher nearby for emergencies.

Engine And Vehicle Setup

Proper setup of the engine and vehicle is key. Follow these steps:

- Raise the front of the vehicle using a jack.

- Support the vehicle with jack stands for stability.

- Remove the engine cover to access the lifters.

- Clean the engine area to prevent contamination.

- Ensure all tools are within reach for convenience.

| Tool | Purpose |

|---|---|

| Socket Wrench | To remove engine parts |

| Feeler Gauge | To measure clearances |

| Screwdriver | For adjustments |

These preparation steps will make the adjustment process smoother. Always prioritize safety and follow the correct setup procedures.

Identifying Hydraulic Lifter Issues

Identifying hydraulic lifter issues early is crucial for engine health. Maladjusted lifters can lead to various engine problems. Understanding the symptoms and performing diagnostic checks can save you time and money.

Common Symptoms Of Maladjustment

Recognizing the common symptoms can help you identify maladjustment quickly. Here are some key signs:

- Engine Noise: Clicking or tapping sounds indicate lifter issues.

- Poor Performance: Reduced power or misfires signal trouble.

- Oil Pressure Drops: Low oil pressure can affect lifters.

- Excessive Exhaust Smoke: Blue or white smoke suggests lifter problems.

Initial Diagnostic Checks

Perform these initial diagnostic checks to identify hydraulic lifter issues:

- Inspect Oil Levels: Ensure the engine has adequate oil.

- Check Oil Quality: Dirty or old oil can affect lifter performance.

- Listen for Noises: Use a mechanic’s stethoscope to pinpoint noises.

- Examine the Valve Train: Look for signs of wear or damage.

Regular maintenance can help prevent hydraulic lifter issues. Always use high-quality oil and keep the engine clean. Identifying and addressing problems early can extend the life of your engine.

Adjustment Process Overview

Adjusting hydraulic roller lifters is essential for engine performance. Proper adjustment ensures smooth operation and longevity. This guide will walk you through the process step-by-step. Let’s dive into the details.

Priming The Lifters

Before you begin, priming the lifters is crucial. This process removes air pockets and ensures proper oil distribution. Follow these steps for effective priming:

- Place the lifters in a container filled with engine oil.

- Use a pushrod to manually pump the lifters.

- Continue pumping until no air bubbles appear.

- Ensure all lifters are fully submerged in oil.

Sequential Steps For Adjustment

Follow these steps to adjust the hydraulic roller lifters:

- Rotate the engine to the top dead center (TDC) on the compression stroke.

- Adjust the first set of lifters according to the firing order.

- Loosen the rocker arm nut until you feel slack.

- Tighten the nut until you feel resistance.

- Turn the nut an additional 1/2 to 3/4 turn to preload the lifter.

- Repeat the process for all remaining lifters in the firing order.

Use the table below for a quick reference on the firing order:

| Cylinder Number | Firing Order |

|---|---|

| 1 | First |

| 3 | Second |

| 4 | Third |

| 2 | Fourth |

Keep these points in mind for accurate adjustment:

- Ensure the engine is cold.

- Use the correct tools for the job.

- Double-check each adjustment for accuracy.

Following these steps will ensure your lifters are correctly adjusted. Proper adjustment leads to better engine performance and longevity.

Fine-tuning Techniques

Fine-tuning hydraulic roller lifters ensures your engine runs smoothly. Proper adjustments enhance performance and extend the engine’s life. Let’s explore the fine-tuning techniques for hydraulic roller lifters.

Achieving Optimal Valve Lash

Achieving optimal valve lash is crucial for engine efficiency. Valve lash is the gap between the rocker arm and the valve stem. This gap must be precise to ensure smooth engine operation.

Follow these steps to achieve the perfect valve lash:

- Turn the engine to the base circle of the cam.

- Use a feeler gauge to measure the gap.

- Adjust the rocker arm until the gauge fits snugly.

Incorrect valve lash can cause engine noise and reduced performance. Consistent checking and adjustment maintain optimal engine function.

Tips For Precision Adjustment

Precision in adjusting hydraulic roller lifters is essential. These tips will help you achieve accurate adjustments:

- Use a calibrated torque wrench for precise settings.

- Ensure the engine is at operating temperature before adjustments.

- Double-check the alignment of the rocker arm and pushrod.

Precision adjustments prevent engine wear and improve performance. Regular maintenance keeps your engine in top condition.

Here are some additional tips:

| Tip | Details |

|---|---|

| Check Oil Pressure | Ensure oil pressure is within the recommended range. |

| Listen for Noise | Listen for unusual noises during adjustments. |

| Use Quality Parts | Use high-quality lifters and components. |

Effective fine-tuning techniques enhance engine reliability and performance. Make these adjustments part of your regular maintenance routine.

Post-adjustment Procedures

After adjusting your hydraulic roller lifters, it’s crucial to follow specific post-adjustment procedures. This ensures optimal engine performance and longevity. Below are the steps you need to follow to complete the process.

Re-checking Lifter Settings

Once the adjustments are made, re-checking the settings is essential. This step ensures that everything is calibrated correctly. Follow these steps:

- Turn the engine manually to reposition the lifters.

- Use a feeler gauge to check gaps.

- Make sure all lifters are snug but not too tight.

If any setting seems off, adjust it again. Precision is key.

Engine Start And Idle Test

After re-checking, start the engine. Let it run at idle. This will help you notice any immediate issues. Follow these steps:

- Start the engine and let it idle.

- Listen for any unusual noises.

- Monitor the engine’s temperature.

- Check the oil pressure gauge.

During the idle test, listen for any clicking sounds. Clicking sounds may indicate improper adjustment. Also, watch the temperature and oil pressure. These indicators help ensure the engine is running smoothly.

If the engine runs smoothly, take it for a short drive. This will further ensure everything is working correctly. If any issues arise, recheck the adjustments.

Troubleshooting Common Issues

Adjusting hydraulic roller lifters is crucial for engine performance. Sometimes, problems can occur. This section will help you troubleshoot common issues.

Dealing With Persistent Noises

Persistent noises can be a sign of a problem. Ensure the lifters are properly lubricated. Lack of lubrication can cause clicking sounds.

Check for worn-out components. Inspect the pushrods and rocker arms. Replace any damaged parts. This can reduce noise.

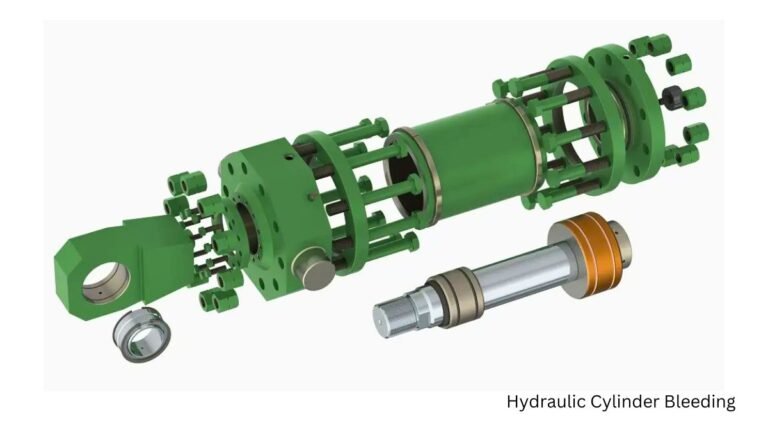

Sometimes, air can get trapped in the lifters. This can cause ticking sounds. Bleed the lifters to remove air bubbles. Follow the manufacturer’s instructions.

When To Seek Professional Help

If noises persist, it might be time to seek help. A mechanic can diagnose complex issues. They have the tools and knowledge to fix problems.

If you notice oil leaks, get professional help. Leaks can damage the engine. They need immediate attention.

Engine performance issues can also be a sign. If the engine misfires or loses power, consult a professional. This can prevent further damage.

| Issue | Possible Cause | Solution |

|---|---|---|

| Persistent Noise | Lack of Lubrication | Lubricate Lifters |

| Ticking Sound | Air Trapped in Lifters | Bleed Lifters |

| Oil Leaks | Worn-out Seals | Replace Seals |

| Engine Misfires | Faulty Lifters | Consult a Mechanic |

Maintenance And Longevity

Hydraulic roller lifters are essential for your engine’s performance. Proper maintenance ensures their longevity. This section covers routine checks and balances, as well as tips for ensuring lifter longevity.

Routine Checks And Balances

Regular inspections are crucial for your hydraulic roller lifters. These checks ensure optimal performance. Here are some routine checks:

- Inspect lifters for wear and tear.

- Check for proper lubrication levels.

- Ensure lifters are free from debris.

Maintaining a routine helps prevent major issues. It keeps your engine running smoothly. Consistent checks extend the life of your lifters.

Ensuring Lifter Longevity

Proper care ensures your lifters last longer. Follow these tips for lifter longevity:

- Use high-quality oil: Quality oil reduces friction.

- Maintain proper oil pressure: Correct pressure is crucial.

- Avoid overheating: Overheating can damage lifters.

Avoid aggressive driving to prolong lifter life. Smooth driving reduces wear. Regular maintenance is key.

Keep your engine clean. Dirt can affect lifter performance. Clean engines ensure better lifter function.

| Maintenance Task | Frequency |

|---|---|

| Inspect lifters | Every 5,000 miles |

| Check lubrication | Monthly |

| Clean engine | Every 3 months |

By following these tips, you can ensure your hydraulic roller lifters perform well. Regular maintenance and care are essential for their longevity.

Maximizing Engine Efficiency

Adjusting hydraulic roller lifters plays a crucial role in maximizing engine efficiency. Proper adjustment ensures that your engine runs smoothly and performs optimally. This section will summarize the key points and provide resources for continued learning.

Recap Of Key Takeaways

Here are the essential points to remember:

- Tools Needed: Wrenches, feeler gauges, and a torque wrench.

- Preparation: Clean the engine and ensure it’s cool.

- Adjustment Process: Follow a step-by-step method for accurate results.

- Double-Check: Recheck adjustments to ensure correctness.

Properly adjusted lifters can prevent engine wear and improve performance. Regular maintenance is key to a healthy engine.

Continued Learning And Resources

For those eager to dive deeper, numerous resources are available:

These resources offer detailed information and expert tips. Regular learning and practice will help you become proficient in adjusting hydraulic roller lifters.

What Are Hydraulic Roller Lifters?

Hydraulic roller lifters are engine components that improve performance. They use hydraulic pressure to adjust valve lash, reducing noise and wear.

How Do Hydraulic Roller Lifters Work?

Hydraulic roller lifters maintain zero valve lash using hydraulic pressure. They adjust automatically, improving engine performance and reducing wear.

Why Adjust Hydraulic Roller Lifters?

Adjusting hydraulic roller lifters ensures optimal engine performance. Proper adjustment reduces noise, improves efficiency, and extends engine life.

When Should You Adjust Hydraulic Roller Lifters?

Adjust hydraulic roller lifters during regular maintenance or if you notice performance issues. Check your vehicle’s manual for specific intervals.

Conclusion

Mastering the adjustment of hydraulic roller lifters boosts engine performance and longevity. Follow the steps carefully for best results. Regular maintenance ensures smooth operation and prevents potential issues. Always consult your vehicle’s manual for specific guidelines. With these tips, you can confidently adjust hydraulic roller lifters for optimal performance.