How Much to Rebuild a Hydraulic Cylinder? Save Big!

To rebuild a hydraulic cylinder, it costs between $200 to $1,500, depending on size and complexity. Prices vary by parts and labor.

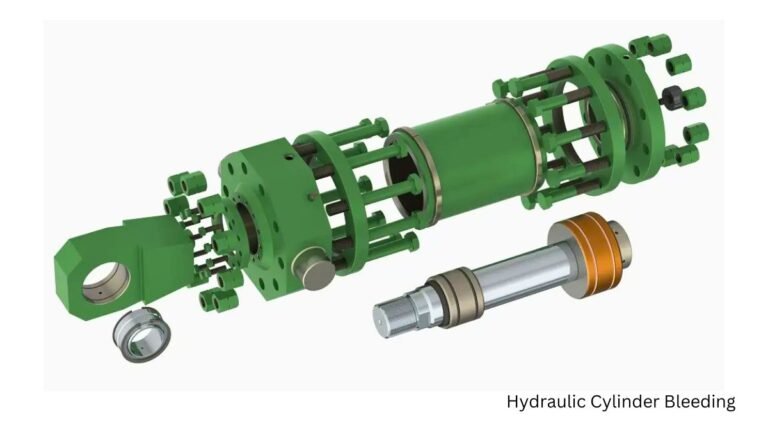

Hydraulic cylinders are crucial components in various machinery, ensuring smooth operation. Regular maintenance can extend their lifespan, but eventually, they may require rebuilding. The cost to rebuild a hydraulic cylinder depends on multiple factors, including the cylinder’s size, type, and the extent of the damage.

Rebuilding typically involves replacing seals, rods, or other parts, and labor costs can also vary. Understanding these factors can help budget for repairs and prevent unexpected expenses. Proper care and timely rebuilding ensure machinery performs efficiently, minimizing downtime and maximizing productivity.

Introduction To Hydraulic Cylinder Rebuilding

Hydraulic cylinders are vital in various industries. They power heavy machinery, construction equipment, and more. Over time, these cylinders wear out and need rebuilding. Rebuilding a hydraulic cylinder involves disassembling, inspecting, and replacing parts. This process ensures the cylinder works like new.

Cost-benefit Analysis

Rebuilding a hydraulic cylinder can be cost-effective. New cylinders are expensive. Rebuilding saves money. The cost of rebuilding varies. It depends on parts, labor, and the cylinder’s condition.

Benefits of rebuilding:

- Lower cost compared to buying new

- Extends the life of the cylinder

- Reduces equipment downtime

- Environmentally friendly

Potential costs:

| Cost Factor | Estimated Cost |

|---|---|

| Parts | $50 – $500 |

| Labor | $70 – $150 per hour |

| Inspection | $100 – $200 |

Significance Of Regular Maintenance

Regular maintenance is crucial for hydraulic cylinders. It prevents major failures. Maintenance includes checking seals, rods, and fluid levels. By maintaining the cylinders, you avoid costly repairs. It also ensures machinery runs smoothly.

Here are some key maintenance tasks:

- Inspect for leaks

- Check and replace seals

- Monitor fluid levels

- Examine rods for damage

Consistent maintenance extends the cylinder’s lifespan. It keeps your equipment operational and safe.

Identifying The Need For Rebuilding

Rebuilding a hydraulic cylinder can be costly. Identifying the need for rebuilding early can save you money. Recognizing the symptoms and assessing the condition is crucial.

Symptoms Of Cylinder Failure

Several signs indicate a failing hydraulic cylinder:

- Leaking fluid: Look for oil around the cylinder.

- Reduced performance: Notice slower operation speeds.

- Unusual noises: Listen for knocking or banging sounds.

- Visible damage: Check for dents or scratches.

Assessing Cylinder Condition

To assess the condition of a hydraulic cylinder, follow these steps:

- Inspect seals and rods: Check for worn or broken seals.

- Check for corrosion: Look for rust on the cylinder surface.

- Test the pressure: Use a gauge to measure hydraulic pressure.

- Evaluate the alignment: Ensure the cylinder is properly aligned.

Rebuilding might be necessary if you notice any of these issues. Early detection can help avoid major repairs and costs.

Factors Influencing Rebuild Costs

Rebuilding a hydraulic cylinder can be a complex task. Several factors affect the total cost. Understanding these factors helps you budget effectively. Below are key influences on rebuild costs.

Material Costs

Material costs play a major role in the overall expense. High-quality materials tend to be more expensive. For instance, steel cylinders cost more than aluminum ones. Prices of seals, rods, and other components also vary.

| Material | Cost per Unit |

|---|---|

| Steel | $50 |

| Aluminum | $30 |

| Seals | $10 |

Labor Rates

Labor rates depend on the expertise required. Skilled technicians demand higher wages. Location also affects labor costs. Urban areas usually have higher labor rates than rural areas.

- Skilled Technician: $80/hour

- Unskilled Labor: $40/hour

Complexity Of Cylinder Design

Complex designs are harder to rebuild. They require more time and specialized tools. Simple designs are easier and cheaper to fix. Custom or rare cylinder designs increase costs significantly.

- Simple Design: Lower Cost

- Complex Design: Higher Cost

- Custom Design: Highest Cost

Diy Vs. Professional Rebuild

Deciding between a DIY rebuild and hiring a professional for your hydraulic cylinder can be tough. Each option has its own set of benefits and drawbacks. This section will help you weigh the pros and cons, so you can make an informed choice.

Pros And Cons Of Diy

Choosing to rebuild a hydraulic cylinder yourself can be both rewarding and challenging. Below are some points to consider:

| Pros | Cons |

|---|---|

| Cost Savings: DIY projects can save you money. | Time-Consuming: Rebuilding takes a lot of time. |

| Learning Experience: Gain valuable skills and knowledge. | Risk of Errors: Mistakes can lead to costly repairs. |

| Control: You have full control over the process. | Special Tools Needed: Requires specific tools and equipment. |

When To Hire A Professional

Sometimes, hiring a professional is the best option. Here are some situations where you should consider it:

- Lack of Experience: If you lack mechanical skills.

- Complex Repairs: For complicated hydraulic systems.

- Time Constraints: When you need a quick turnaround.

- Quality Assurance: Professionals guarantee their work.

A professional rebuild can save you from potential headaches. They have the expertise to ensure the job is done right.

Estimating Your Rebuild Costs

Rebuilding a hydraulic cylinder involves various costs. Calculating these costs helps in budgeting. Let’s break down these expenses.

Tools And Supplies Needed

Gathering the right tools is essential. Here’s a list of basic tools and supplies:

- Wrenches and Sockets – For loosening and tightening bolts.

- Seal Kits – To replace old, worn-out seals.

- Cleaning Solvents – To clean the cylinder parts.

- Lubricants – For smooth reassembly.

- Gauges – To measure pressure and alignment.

Each of these tools has a cost. The total cost varies based on quality. Budget for high-quality tools for better results.

Calculating Labor Expenses

Labor expenses depend on several factors. Consider the following:

| Factor | Details | Estimated Cost |

|---|---|---|

| Experience Level | Skilled labor costs more | $50 – $100 per hour |

| Time Required | Complex repairs take longer | 5 – 10 hours |

| Location | Costs vary by region | Varies |

To estimate labor costs, multiply hours by the hourly rate. For example, if a rebuild takes 8 hours and the rate is $75 per hour, the labor cost is $600.

Remember to factor in additional costs for unexpected issues. Having a buffer in your budget is wise.

Step-by-step Rebuilding Process

Rebuilding a hydraulic cylinder can save you money and extend its life. The process requires careful attention and the right tools. Below, we’ll break down the steps in detail.

Disassembly Tips

Start by cleaning the cylinder to remove dirt and grime. Secure the cylinder in a vice, ensuring it is stable. Use the right tools to remove the end cap, piston, and rod. Label each part to keep track of them.

- Use a soft brush to clean parts.

- Inspect each part for wear or damage.

- Keep a record of all disassembled parts.

Seal Replacement

Seals are crucial for cylinder performance. Replace old seals with new ones. Ensure you use the correct type of seals for your cylinder model.

| Seal Type | Function |

|---|---|

| Rod Seal | Prevents fluid leakage along the rod. |

| Piston Seal | Ensures proper pressure distribution. |

| Wiper Seal | Keeps contaminants out of the cylinder. |

Reassembly And Testing

Reassemble the cylinder by reversing the disassembly steps. Make sure all parts are clean before reassembling. Tighten all fittings to the manufacturer’s specifications.

- Insert the piston and rod into the cylinder.

- Replace the end cap and secure it tightly.

- Test the cylinder for leaks and proper function.

Testing is crucial to ensure the cylinder works correctly. Use a hydraulic test bench for accurate results. Check for any fluid leaks and ensure smooth operation.

Maximizing Cost Savings

Rebuilding a hydraulic cylinder can be expensive. But, you can save money. Here are some smart ways to cut costs without sacrificing quality.

Bulk Buying Of Parts

Buying parts in bulk can save you money. Suppliers often give discounts for large orders. You can also reduce shipping costs. Store the extra parts for future use. This ensures you have what you need when something breaks.

Reusing Components

Don’t throw away old components if they are still good. Inspect parts like seals and rods carefully. Clean and refurbish them if possible. This can save a lot on new parts. Always ensure re-used parts are up to standard.

Preventive Measures

Regular maintenance can prevent big problems. Check your hydraulic cylinder often. Look for leaks, cracks, or worn-out parts. Fix small issues quickly to avoid costly repairs. Keep a log of all maintenance activities. This helps in tracking the health of your system.

Here are some tips for preventive measures:

- Change the hydraulic fluid regularly.

- Inspect seals and rods for wear and tear.

- Clean the cylinder to remove any debris.

Preventive measures save money and extend the life of your hydraulic cylinder.

Common Mistakes To Avoid

Rebuilding a hydraulic cylinder can save money and extend its lifespan. But common mistakes can lead to costly repairs and downtime. Knowing these mistakes helps you avoid them and rebuild your hydraulic cylinder successfully.

Incorrect Part Selection

Choosing the wrong parts can cause big problems. Always match parts to the cylinder’s specifications. Use the manufacturer’s guidelines to ensure compatibility. A mismatch can lead to leaks and poor performance.

Improper Installation Techniques

Proper installation is crucial for cylinder efficiency. Follow the recommended installation procedures to avoid issues. Use the right tools and techniques. Tighten bolts to the specified torque to prevent leaks and ensure a secure fit.

Here’s a quick checklist for proper installation:

- Use correct tools.

- Follow manufacturer guidelines.

- Check torque specifications.

- Inspect for leaks after installation.

Incorrect installation can lead to premature failure. Always double-check your work and ensure everything is properly secured.

Long-term Benefits Of A Quality Rebuild

Rebuilding a hydraulic cylinder can seem costly. But, investing in quality parts and services offers many long-term benefits. This section will explore these benefits.

Enhanced Performance

A quality rebuild ensures your hydraulic cylinder performs like new. Enhanced performance means your machinery will run more efficiently. You can handle bigger loads and complete tasks faster. This boosts productivity and reduces downtime.

Rebuilt cylinders also offer smoother operation. The components fit better and work in harmony. This reduces wear and tear. You will experience fewer breakdowns and repairs.

Extended Cylinder Lifespan

Investing in a quality rebuild extends the life of your hydraulic cylinder. Extended cylinder lifespan means you won’t need replacements as often. A well-rebuilt cylinder can last as long as a new one. This saves money in the long run.

Using high-quality parts ensures durability. These parts can withstand harsh conditions better. Your cylinder will perform well in tough environments. This reduces the risk of failure.

| Benefit | Description |

|---|---|

| Enhanced Performance | Increased efficiency, handling bigger loads, smoother operation, fewer breakdowns. |

| Extended Lifespan | Longer life span, less frequent replacements, durability in harsh conditions. |

Rebuilding a hydraulic cylinder is a wise investment. The long-term benefits make it worth the cost.

What Factors Affect Hydraulic Cylinder Rebuild Cost?

The cost to rebuild a hydraulic cylinder depends on size, complexity, and parts needed. Labor rates and geographic location also influence pricing. Shop rates vary widely.

How Long Does A Hydraulic Cylinder Rebuild Take?

Rebuilding a hydraulic cylinder typically takes 1 to 5 days. Duration depends on complexity, parts availability, and shop workload. Expedite options may be available.

Can I Rebuild A Hydraulic Cylinder Myself?

Yes, if you have the right tools and skills. However, professional services ensure quality and safety. DIY can save money but may void warranties.

What Is The Average Cost To Rebuild A Hydraulic Cylinder?

The average cost to rebuild a hydraulic cylinder ranges from $200 to $800. Prices vary based on size, parts, and labor rates. Always get a quote.

Conclusion

Rebuilding a hydraulic cylinder can vary greatly in cost. Factors include parts, labor, and cylinder size. Always get quotes from reputable shops. Regular maintenance can help avoid costly repairs. Understanding these elements can help you budget effectively. Keep your equipment running smoothly and efficiently by staying informed.