How Do You Measure A Hydraulic Cylinder? Accurate Tips

To measure a hydraulic cylinder, measure the piston rod’s diameter and the cylinder’s stroke length. Ensure the cylinder is fully extended.

Hydraulic cylinders are essential components in various machinery and equipment. Accurate measurement is crucial for proper maintenance and replacement. The two primary dimensions are the piston rod diameter and the stroke length. The piston rod diameter is the thickness of the rod, while the stroke length is the distance the rod travels when fully extended.

These measurements ensure compatibility with your machinery. Proper measurement helps avoid malfunctions and ensures smooth operation. Always double-check measurements for accuracy. Understanding these dimensions can save time and prevent costly errors. This guide provides a straightforward approach to measuring hydraulic cylinders effectively.

Introduction To Hydraulic Cylinder Measurement

Hydraulic cylinders power many machines. Measuring them correctly is crucial. This ensures they work well and last longer. Learn how to measure a hydraulic cylinder accurately.

Importance Of Accurate Measurements

Accurate measurements ensure the cylinder fits perfectly. It prevents leaks and breakdowns. Incorrect measurements can cause machine failure. Accurate data helps in maintenance and replacement. It also ensures safety and efficiency.

Basic Components Of A Hydraulic Cylinder

A hydraulic cylinder has several key parts. Each part is crucial for its function. Here are the main components:

- Barrel: The main body of the cylinder.

- Rod: The moving part that extends and retracts.

- Piston: Attached to the rod, moves within the barrel.

- Seals: Prevent fluid leaks.

- End caps: Close the ends of the barrel.

Understanding these parts helps in accurate measurement.

| Component | Description |

|---|---|

| Barrel | Main body of the cylinder |

| Rod | Extends and retracts |

| Piston | Moves within the barrel |

| Seals | Prevent fluid leaks |

| End caps | Close the ends of the barrel |

To measure a hydraulic cylinder, you need to understand each part’s function.

Preparation For Measurement

Before you start measuring a hydraulic cylinder, proper preparation is crucial. Ensure you have all the necessary tools and follow safety precautions.

Tools Required For Measuring

To measure a hydraulic cylinder accurately, gather the following tools:

- Calipers – For precise measurements.

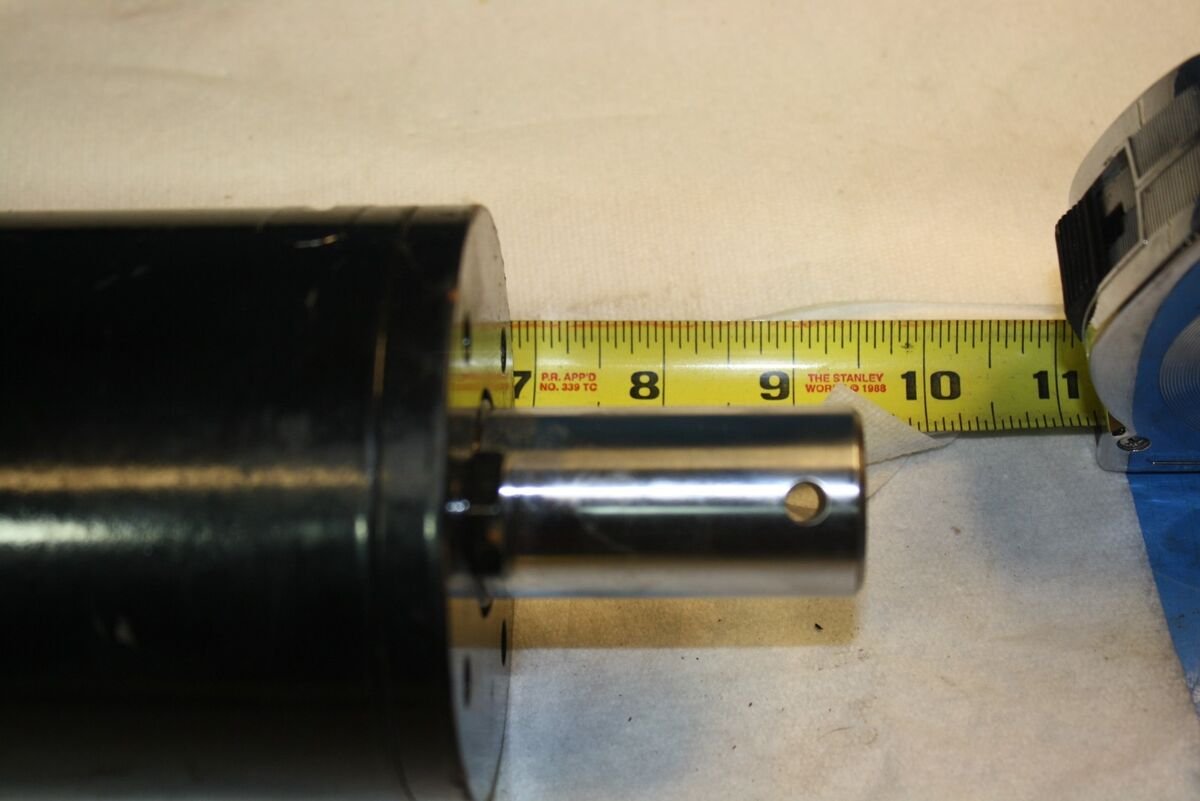

- Measuring Tape – For length and diameter.

- Micrometer – For small and precise measurements.

- Cleaning Cloth – To clean the cylinder before measuring.

Safety Precautions

Always prioritize safety when measuring a hydraulic cylinder. Follow these safety tips:

- Wear Safety Goggles – Protect your eyes from debris.

- Use Gloves – Keep your hands safe from sharp edges.

- Ensure Stability – Make sure the cylinder is stable before measuring.

- Work in a Clean Area – Avoid clutter to prevent accidents.

| Tool | Purpose |

|---|---|

| Calipers | For precise measurements |

| Measuring Tape | For length and diameter |

| Micrometer | For small and precise measurements |

| Cleaning Cloth | To clean the cylinder |

Determining Cylinder Dimensions

Knowing the exact dimensions of a hydraulic cylinder is crucial. Accurate measurements ensure the cylinder works efficiently. This section will guide you through the process. We will cover two main aspects: measuring the cylinder bore and calculating the rod diameter.

Measuring Cylinder Bore

The cylinder bore is the inner diameter of the cylinder. To measure it, follow these steps:

- Use a bore gauge or a caliper.

- Insert the tool into the cylinder.

- Take the measurement at several points.

- Calculate the average for accuracy.

Accurate bore measurements ensure proper cylinder performance. Bore size impacts the cylinder’s power. Larger bores produce more force.

Calculating Rod Diameter

The rod diameter is the thickness of the rod inside the cylinder. Follow these steps to measure it:

- Use a caliper for precision.

- Place the caliper around the rod.

- Read the measurement on the caliper.

The rod diameter affects the cylinder’s strength. A thicker rod can handle more pressure. Always ensure you measure the rod accurately.

Below is a table for quick reference:

| Measurement Type | Tool Required | Steps |

|---|---|---|

| Bore | Bore Gauge/Caliper | Insert, Measure, Average |

| Rod Diameter | Caliper | Place, Read |

These measurements are essential for hydraulic cylinder efficiency. Ensure to use precise tools. Accuracy in measurements leads to better performance.

Assessing Cylinder Stroke Length

Measuring the stroke length of a hydraulic cylinder is crucial. This measurement helps in determining the efficiency and suitability of the cylinder for specific tasks. It’s essential to understand the extended and retracted lengths to get accurate stroke length measurements. Below are some key aspects to consider.

Extended Vs Retracted Length

The extended length refers to the total length of the cylinder when fully extended. This includes the length of the piston rod and the cylinder body. The retracted length is the cylinder’s length when fully retracted, which is the shortest possible length. Knowing these two measurements helps in calculating the stroke length effectively.

| Measurement Type | Description |

|---|---|

| Extended Length | Total length when the piston rod is fully extended. |

| Retracted Length | Shortest length when the piston rod is fully retracted. |

Techniques For Stroke Measurement

Several techniques can be employed to measure the stroke length of a hydraulic cylinder. The following methods are commonly used:

- Manual Measurement: Use a tape measure to find the extended and retracted lengths. Subtract the retracted length from the extended length.

- Digital Calipers: These can give precise measurements. Place the calipers at the base and extend to the tip of the piston rod.

- Linear Transducers: Electronic devices that measure the position of the piston rod. These are useful for real-time monitoring.

Manual measurement is the simplest method. Digital calipers provide more precision, while linear transducers offer real-time data. Choose the method that best fits your needs.

Evaluating Rod Extension

Measuring the rod extension of a hydraulic cylinder is essential for accuracy. Proper measurement ensures the cylinder functions correctly. This section explains how to measure rod extension effectively.

Rod Extension Measurement Methods

Different methods can measure the rod extension of a hydraulic cylinder. Below are the most common approaches:

- Direct Measurement: Use a tape measure to check the length of the rod.

- Vernier Caliper: A caliper provides precise measurements. It is useful for smaller rods.

- Dial Indicator: This tool measures the extension during operation. It provides real-time data.

Common Mistakes To Avoid

Many people make mistakes while measuring rod extension. Here are some common errors to watch for:

- Ignoring Zero Calibration: Always calibrate your measuring tool to zero before use.

- Incorrect Angle: Ensure the measuring tool is parallel to the rod. Angles can distort measurements.

- Dirty Rod: Dirt or debris on the rod can affect the measurement. Clean the rod first.

Understanding these methods and avoiding common mistakes can ensure accurate rod extension measurements. Precision is key in maintaining hydraulic systems.

Mounting Style Considerations

Understanding mounting styles is crucial for measuring a hydraulic cylinder accurately. Different mounting styles affect how you measure the cylinder’s length and stroke. This section will guide you through the key considerations for various mounting styles.

Identifying Mounting Types

Before you measure, you must identify the mounting type of the hydraulic cylinder. Mounting types include:

- Flange Mount

- Trunnion Mount

- Clevis Mount

- Eye Mount

Each type has unique features and measurement points. Recognizing these will help you get accurate measurements. For example, a flange mount has a flat surface, while a clevis mount has a U-shaped bracket.

Impact On Measurement Procedure

The mounting style impacts the measurement procedure significantly. Let’s break it down:

| Mounting Type | Measurement Points |

|---|---|

| Flange Mount | Measure from the flange base to the rod end |

| Trunnion Mount | Measure from trunnion center to the rod end |

| Clevis Mount | Measure from pin center to the rod end |

| Eye Mount | Measure from eye center to the rod end |

Each mounting style requires different starting and ending points for measurements. Understanding these points ensures accurate data.

For a clevis mount, you measure from the pin center. For a trunnion mount, measure from the trunnion center. Each type has its unique approach.

Recording And Interpreting Results

Recording and interpreting results are critical steps in measuring a hydraulic cylinder. Proper documentation and analysis ensure accurate assessments. This section covers best practices for documentation and tips for analyzing measurement data.

Documentation Best Practices

Proper documentation ensures all measurements are recorded accurately. Use a consistent format to avoid confusion. Here are some best practices:

- Use a dedicated logbook or digital tool for recording measurements.

- Record date, time, and conditions during each measurement.

- Include all relevant details like cylinder type and size.

- Double-check entries for accuracy and completeness.

- Use clear and concise language for notes and observations.

Analyzing Measurement Data

Analyzing measurement data helps identify trends and inconsistencies. Follow these steps to interpret your results:

- Compare current measurements with previous data to spot trends.

- Look for outliers that may indicate measurement errors.

- Use graphs or charts to visualize data trends.

- Consult with experts if data patterns are unclear.

Here’s a sample table to help organize your measurement data:

| Date | Time | Condition | Cylinder Type | Measurement |

|---|---|---|---|---|

| 2023-10-01 | 10:00 AM | Normal | Single-Acting | 150 mm |

| 2023-10-02 | 11:00 AM | High Pressure | Double-Acting | 155 mm |

Maintenance And Troubleshooting

Proper maintenance of a hydraulic cylinder ensures its longevity. Troubleshooting helps identify and fix issues early. Regular inspections and addressing discrepancies are key steps.

Regular Inspection Schedules

Regular inspection schedules are vital. They help catch problems early. Create a timetable for checks.

| Frequency | Inspection Points |

|---|---|

| Daily | Check for leaks, clean external surfaces |

| Weekly | Inspect seals, check fluid levels |

| Monthly | Test cylinder pressure, inspect for wear |

| Yearly | Complete overhaul, replace worn parts |

Addressing Measurement Discrepancies

Measurement discrepancies indicate potential issues. Address them promptly.

- Recalibrate the measuring tools.

- Inspect for worn or damaged components.

- Replace faulty parts.

Incorrect measurements can lead to bigger problems. Always use accurate tools.

- Use a caliper for precise measurements.

- Check the cylinder’s stroke length.

- Verify the bore diameter.

Keep a record of all measurements. This helps track changes over time.

Advanced Measurement Techniques

Measuring a hydraulic cylinder accurately is critical. Advanced measurement techniques enhance precision and efficiency. Digital tools and professional services can offer superior results. Let’s explore these methods in detail.

Utilizing Digital Tools

Digital tools provide precise measurements. These tools reduce human error.

- Laser Measurement Devices: These devices use laser beams. They measure the cylinder’s length accurately.

- Digital Calipers: Calipers are essential for measuring the cylinder’s bore and rod. Digital versions offer more accuracy.

- Ultrasonic Thickness Gauges: These tools measure the cylinder’s wall thickness. They use sound waves to provide exact measurements.

Using digital tools saves time. They ensure more reliable data.

Engaging Professional Services

Sometimes, measuring a hydraulic cylinder requires expert help. Professional services bring specialized knowledge and tools.

- Consulting Engineers: Engineers can provide detailed assessments. They understand the complexities of hydraulic systems.

- Specialized Measurement Firms: These firms use advanced tools. They offer precise and comprehensive measurements.

- Certified Inspectors: Inspectors ensure measurements meet industry standards. They check for compliance and safety.

Engaging professionals ensures accuracy. It also helps in maintaining standards.

Consider the measurement environment. Temperature and pressure can affect results. Choose the right method for your specific needs.

What Tools Do I Need To Measure A Hydraulic Cylinder?

To measure a hydraulic cylinder, you need a tape measure, calipers, and a straight edge. These tools help ensure accuracy.

How Do I Measure The Bore Size?

Measure the internal diameter of the cylinder tube using calipers. This gives you the bore size.

What Is The Stroke Length In A Hydraulic Cylinder?

Stroke length is the distance the piston travels inside the cylinder. Measure it with a tape measure.

How Do I Find The Rod Diameter?

Measure the diameter of the piston rod using calipers. This gives you the rod diameter.

Conclusion

Measuring a hydraulic cylinder accurately ensures optimal performance. Follow the steps outlined to get precise measurements. Proper measurement leads to efficient operation and extends cylinder lifespan. Remember, accurate measurements save time and money. Use the right tools and techniques for best results.

With careful attention, your hydraulic system will function smoothly.