Can You Use Engine Oil As Hydraulic Oil? Myths Busted!

You should not use engine oil as hydraulic oil. They have different properties and formulations.

Hydraulic systems require specific fluids designed to optimize performance and longevity. Engine oil and hydraulic oil serve distinct purposes. Engine oil primarily lubricates engine parts, while hydraulic oil transmits power within hydraulic machinery. Using engine oil in a hydraulic system can lead to equipment damage and reduced efficiency.

Hydraulic oil contains additives for anti-wear, corrosion resistance, and optimal viscosity. Engine oil lacks these essential properties. Proper fluid selection ensures system reliability and efficiency. Always refer to manufacturer guidelines for the correct hydraulic fluid. Using the right oil is critical for maintaining the integrity and performance of hydraulic systems.

Introduction To Hydraulic And Engine Oils

Choosing the right oil for your machinery ensures smooth operation. Understanding the differences between hydraulic oil and engine oil is crucial. They serve unique purposes and have distinct properties.

Key Properties Of Hydraulic Oil

Hydraulic oil is designed to transfer power within hydraulic systems. It has specific properties that make it suitable for this task.

- Viscosity: Hydraulic oil maintains a stable viscosity across temperatures.

- Anti-wear: It contains additives that minimize wear and tear.

- Thermal stability: It resists thermal degradation.

- Anti-corrosion: Protects hydraulic components from rust and corrosion.

Primary Functions Of Engine Oil

Engine oil is formulated to perform several vital functions within an engine. It is crucial for maintaining engine health.

- Lubrication: Reduces friction between engine parts.

- Cooling: Helps dissipate heat from the engine.

- Cleaning: Contains detergents that clean engine components.

- Sealing: Aids in sealing gaps between engine parts.

| Property | Hydraulic Oil | Engine Oil |

|---|---|---|

| Viscosity | Stable across temperatures | Varies with temperature |

| Anti-wear | High | Moderate |

| Thermal stability | High | Moderate |

| Anti-corrosion | High | Moderate |

| Lubrication | Moderate | High |

| Cooling | Moderate | High |

| Cleaning | Low | High |

| Sealing | Low | High |

Common Misconceptions About Oil Interchangeability

Many people think engine oil and hydraulic oil are the same. This is a big mistake. Each oil has a unique purpose. Using the wrong oil can cause serious problems.

Myth Versus Reality

Some believe oil is just oil. This is not true. Engine oil and hydraulic oil have different formulas. Engine oil helps in reducing friction in engines. Hydraulic oil transfers power in hydraulic systems. They have different additives and properties.

Risks Of Using The Wrong Oil

Using engine oil instead of hydraulic oil can damage your system. Here are some risks:

- Increased Wear and Tear: The wrong oil can cause parts to wear out faster.

- System Failure: Hydraulic systems might fail if the wrong oil is used.

- Reduced Efficiency: Your machinery may not work as well as it should.

| Type of Oil | Purpose |

|---|---|

| Engine Oil | Reduces friction in engines |

| Hydraulic Oil | Transfers power in hydraulic systems |

Chemical Composition Of Oils

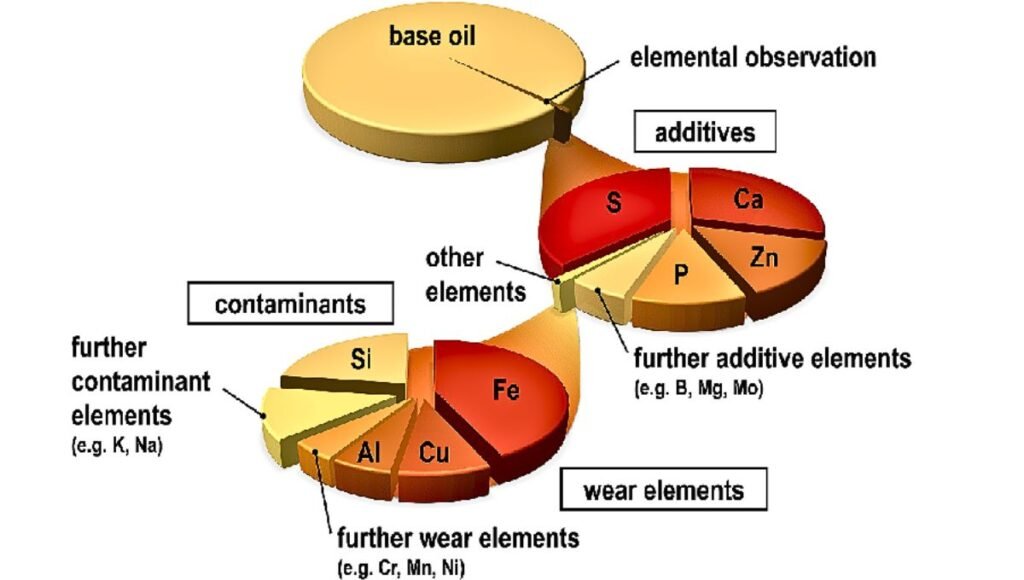

The chemical composition of oils varies greatly based on their intended use. Understanding these differences is crucial for determining their interchangeability. Here, we will explore the additives in engine oil and the ingredients in hydraulic oil.

Additives In Engine Oil

Engine oils contain a variety of additives to enhance performance. Below is a table summarizing the common additives found in engine oils:

| Type of Additive | Function |

|---|---|

| Detergents | Clean engine deposits |

| Dispersants | Prevent sludge formation |

| Anti-wear agents | Reduce friction and wear |

| Viscosity index improvers | Maintain viscosity across temperatures |

| Antioxidants | Prevent oil oxidation |

Hydraulic Oil Ingredients

Hydraulic oils are specially formulated to transmit power efficiently. They contain specific ingredients to serve this purpose:

- Base Oil: Forms the majority of the fluid.

- Anti-wear Additives: Protects hydraulic components.

- Foam Inhibitors: Reduce foam formation.

- Corrosion Inhibitors: Prevent rust and corrosion.

- Viscosity Modifiers: Ensure stable viscosity.

These ingredients ensure hydraulic oil performs its functions effectively. Each ingredient has a specific role that contributes to the overall efficiency.

Viscosity And Why It Matters

Viscosity is a critical factor in oil performance. It measures how thick or thin a liquid is. Different applications require specific viscosity levels. Using the wrong viscosity can lead to equipment failure.

Viscosity Ratings Explained

Viscosity ratings help identify the thickness of the oil. These ratings are often provided by the Society of Automotive Engineers (SAE). For example, SAE 10W-30 oil has a certain viscosity at different temperatures.

| Viscosity Grade | Low Temperature (°C) | High Temperature (°C) |

|---|---|---|

| 5W-30 | -30 | 100 |

| 10W-40 | -25 | 100 |

Engine oils and hydraulic oils have different viscosity needs. Hydraulic systems often require more consistent viscosity. This ensures smooth operation.

Impact Of Viscosity On Oil Performance

Viscosity affects how oil flows and lubricates. High viscosity oils are thicker. They provide better lubrication but can slow down machinery. Low viscosity oils are thinner. They flow easily but may not protect as well.

In hydraulic systems, consistent viscosity is crucial. The system relies on a specific flow rate. Using engine oil in hydraulic systems can cause problems. The viscosity may not remain consistent.

- High Viscosity: Better lubrication but slower machinery.

- Low Viscosity: Easier flow but less protection.

- Consistent Viscosity: Essential for hydraulic systems.

Choosing the right oil ensures the equipment runs smoothly. It also prevents wear and tear. Always check the manufacturer’s recommendations.

The Role Of Heat And Pressure

Understanding the role of heat and pressure in oil systems is crucial. Both engine oil and hydraulic oil face different challenges. Let’s explore how heat and pressure impact these oils.

Engine Oil Under High Temperature

Engine oil operates in a high-temperature environment. The engine produces intense heat. This oil must resist thermal breakdown. It needs to maintain its viscosity to protect engine parts. High temperatures can cause engine oil to thin. This reduces its ability to lubricate.

Engine oil must also combat oxidation. High heat speeds up oxidation, causing oil to degrade. Additives in engine oil help fight oxidation. These additives ensure engine oil remains effective under heat.

Here is a table showing key properties of engine oil under high temperature:

| Property | Description |

|---|---|

| Viscosity | Resists thinning at high temperatures |

| Oxidation Resistance | Prevents oil breakdown due to heat |

| Thermal Stability | Maintains performance under extreme heat |

Hydraulic Oil In Pressure Systems

Hydraulic oil works in systems with high pressure. These systems rely on oil to transfer power. Hydraulic oil must resist compressibility. It needs to maintain its volume under pressure. Compressibility can impact system performance.

Hydraulic oil must also have good lubricity. This reduces friction between moving parts. High pressure can cause wear and tear. Good lubricity helps protect system components.

Here are key properties of hydraulic oil in pressure systems:

- Compressibility: Maintains volume under high pressure

- Lubricity: Reduces friction and wear

- Thermal Stability: Performs well under varying temperatures

Both oils are vital, but their roles differ. Engine oil handles heat, while hydraulic oil manages pressure. Understanding these differences helps in choosing the right oil for your system.

Potential Damage From Incorrect Oil Use

Using the wrong oil in your machinery can cause significant damage. Engine oil and hydraulic oil have different properties. Mistaking one for the other can lead to severe consequences.

Wear And Tear On Engine Parts

Engine oil is designed for lubrication and cooling in engines. It has additives that protect engine parts from friction and heat. Using engine oil in a hydraulic system can cause excessive wear and tear on engine parts.

Hydraulic systems require oil that can handle high pressure. Engine oil cannot withstand this pressure. This leads to increased friction and wear on components.

Impact On Hydraulic Systems

Hydraulic oil is formulated to transfer power effectively. It has specific properties for this purpose. Engine oil lacks these properties. Using engine oil in a hydraulic system can cause system failure.

Hydraulic systems have seals and valves that need proper lubrication. Engine oil can cause these seals to wear out faster. This can lead to leaks and loss of efficiency.

| Engine Oil | Hydraulic Oil |

|---|---|

| Designed for engines | Designed for hydraulic systems |

| Contains friction-reducing additives | Handles high pressure |

| Not suitable for seals and valves | Protects seals and valves |

Using the right oil ensures the longevity of your machinery. Always check the manufacturer’s recommendations for oil types. This simple step can save you from costly repairs and downtime.

Expert Opinions On Oil Substitution

Many people wonder if engine oil can be used as hydraulic oil. Experts have a lot to say on this topic. It’s important to understand their opinions.

Industry Standards For Oil Use

Industry standards specify the correct oil type for each application. Engine oil is designed for engines. Hydraulic oil is made for hydraulic systems. Each oil has specific properties and additives. These differences matter in their performance.

| Oil Type | Primary Use | Key Properties |

|---|---|---|

| Engine Oil | Engines | High temperature stability, anti-wear additives |

| Hydraulic Oil | Hydraulic Systems | Low compressibility, anti-foam additives |

Professional Advice On Oil Selection

Professionals advise against using engine oil as hydraulic oil. Hydraulic systems need specific oil properties. Using the wrong oil can cause damage.

- Engine oil may not have the right viscosity for hydraulic systems.

- Hydraulic oil has additives to prevent foaming.

- Wrong oil can lead to system failure.

Experts recommend always using the specified oil type. This ensures the longevity and efficiency of your machinery. Never substitute engine oil for hydraulic oil without consulting a professional.

Proper Oil Maintenance And Replacement

Proper oil maintenance is crucial for machinery. This ensures longer life and efficiency. Whether using hydraulic oil or engine oil, proper care is essential. Let’s explore tips and intervals for oil maintenance.

Tips For Hydraulic Oil Care

Maintaining hydraulic oil is important. Follow these tips:

- Check oil levels regularly. This prevents machinery failure.

- Use the correct oil type. Different machines need different oils.

- Keep the oil clean. Contaminated oil can harm the machine.

- Replace oil filters. Clean filters ensure efficient operation.

Engine Oil Change Intervals

Engine oil must be changed regularly. This keeps the engine running smoothly. Here are some guidelines:

- Check the owner’s manual. Follow the recommended intervals.

- Monitor oil color and consistency. Dark or thick oil needs changing.

- Consider driving conditions. Severe conditions may need frequent changes.

Use this table for a quick reference:

| Driving Condition | Oil Change Interval |

|---|---|

| Normal | Every 5,000 miles |

| Severe | Every 3,000 miles |

Best Practices For Oil Use

Choosing the right oil is essential for machinery health. Using the wrong oil can cause damage. This section covers best practices for oil use.

Summarizing The Risks Of Improper Oil Use

Using engine oil as hydraulic oil can lead to serious issues. Engine oil and hydraulic oil have different properties. Here are the main risks:

- Increased Wear and Tear: Hydraulic systems need specific lubrication. Engine oil may not provide it.

- System Failure: Incompatible oils can cause system failure. This can lead to costly repairs.

- Reduced Efficiency: Using the wrong oil can reduce machine efficiency. This impacts performance.

Final Recommendations For Oil Selection

Follow these best practices for selecting oil:

- Consult the Manual: Always check the machine’s manual. Use the recommended oil type.

- Check Oil Compatibility: Ensure the oil meets system requirements. Look for specific properties.

- Regular Maintenance: Schedule regular maintenance checks. Replace oil as needed.

- Use High-Quality Oil: Invest in high-quality oil. It ensures better performance.

| Oil Type | Recommended Use |

|---|---|

| Engine Oil | Lubricating engine components |

| Hydraulic Oil | Powering hydraulic systems |

By following these best practices, you can ensure machinery longevity. Proper oil use is key to efficient operation.

Can Engine Oil Replace Hydraulic Oil?

No, engine oil cannot replace hydraulic oil. Hydraulic systems require specific viscosity and additives. Using engine oil can damage the system.

What Happens If You Mix Engine Oil With Hydraulic Oil?

Mixing engine oil with hydraulic oil can cause poor lubrication. It may lead to increased wear and potential system failure.

Are There Alternatives To Hydraulic Oil?

Yes, there are alternatives like vegetable-based oils. However, you should always use the manufacturer-recommended hydraulic fluid.

Can Using Engine Oil In Hydraulics Void The Warranty?

Yes, using engine oil in hydraulics can void the warranty. Always use the recommended hydraulic fluid to ensure warranty compliance.

Conclusion

Using engine oil as hydraulic oil is not advisable. Engine oil lacks the necessary properties for hydraulic systems. It’s crucial to use the correct fluid to ensure optimal performance and longevity. Always refer to the manufacturer’s guidelines for the best results.

Proper maintenance can prevent costly repairs and ensure safety.