Can You Over Tighten Hydraulic Lifters? Avoid Engine Damage!

Yes, you can over-tighten hydraulic lifters. This can cause improper engine function and damage.

Hydraulic lifters play a crucial role in ensuring the smooth operation of an engine. They help maintain proper valve clearance, ensuring optimal performance. Over-tightening these lifters can lead to several issues, including reduced engine efficiency and potential mechanical failure. Proper installation and adjustment are essential to prevent such problems.

Always refer to the manufacturer’s guidelines for correct torque specifications. Ensuring that hydraulic lifters are neither too tight nor too loose can help maintain engine health and longevity. Regular maintenance and checks can avoid costly repairs and enhance overall vehicle performance.

The Mechanics Of Hydraulic Lifters

Understanding the mechanics of hydraulic lifters is crucial for engine performance. Hydraulic lifters play a vital role in maintaining valve operation. They ensure the engine runs smoothly and efficiently.

How Hydraulic Lifters Operate

Hydraulic lifters use oil pressure to adjust valve clearance. This process helps in reducing engine noise and wear. They work by using a small plunger inside a cylinder. Oil enters the lifter and fills a chamber inside the plunger.

As the engine runs, the lifter adjusts to keep the valve lash at zero. This ensures the valve opens and closes at the right times. The lifter’s ability to self-adjust makes it different from solid lifters.

Key Components In Lifter Functionality

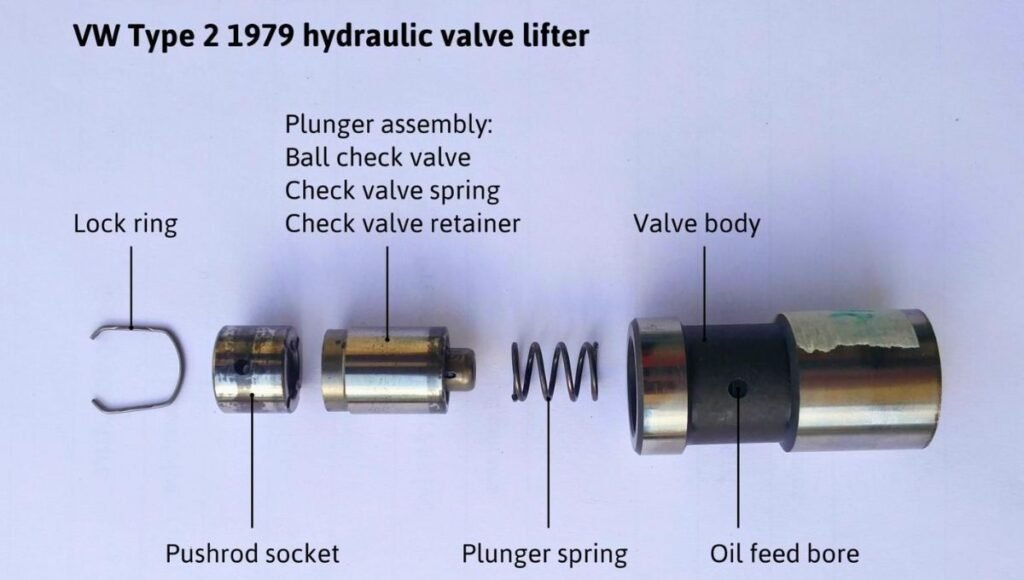

Hydraulic lifters have several important parts. Here are the key components:

- Plunger: The main moving part inside the lifter.

- Body: The outer casing that holds the plunger.

- Check Valve: Controls oil flow into the plunger chamber.

- Spring: Keeps the plunger in position when the engine is off.

These components work together to maintain proper valve operation. The plunger and body interact to adjust valve clearance. The check valve ensures the right amount of oil enters the chamber. The spring ensures the plunger returns to its position when the engine stops.

Understanding these components can help in diagnosing issues. Knowing how they work can prevent over-tightening hydraulic lifters. Proper maintenance ensures long-lasting engine performance.

Symptoms Of Over Tightened Hydraulic Lifters

Over tightening hydraulic lifters can lead to several issues. Understanding the symptoms helps in diagnosing the problem early. Below, we discuss some common symptoms you might notice.

Unusual Engine Noises

One of the first signs is unusual engine noises. These noises can be loud and alarming.

- Tapping Sound: A distinct tapping sound may come from the engine.

- Knocking Noise: You might hear a persistent knocking noise.

- Ticking Sound: A ticking sound can indicate lifter problems.

These noises often occur due to improper lifter clearance. The metal parts may be clashing, causing noise.

Reduced Engine Performance

Another major symptom is reduced engine performance. Over tightened lifters can affect engine efficiency.

| Symptom | Description |

|---|---|

| Poor Acceleration | The car may accelerate slower than usual. |

| Decreased Power | The engine may feel less powerful. |

| Rough Idling | The engine might idle roughly when at a stop. |

These symptoms are often accompanied by a drop in fuel efficiency. The engine has to work harder to perform.

Risks Of Over Tightening

Over tightening hydraulic lifters can lead to serious issues. It’s important to understand these risks. This helps maintain engine health and performance.

Potential For Engine Damage

One major risk is potential engine damage. Over tightening can cause excessive wear on lifters. This leads to engine parts wearing out faster.

Damaged lifters can break or malfunction. This results in significant engine problems. These include oil leaks and loss of engine power.

Excessive wear on lifters means higher repair costs. It can also lead to engine failure. Regular checks can prevent this.

Impact On Valve Timing

Another risk is the impact on valve timing. Over tightening affects how valves open and close. This disrupts the engine’s timing sequence.

Poor valve timing reduces engine efficiency. It can also lead to valve damage. This is costly and time-consuming to fix.

Maintaining proper valve timing ensures smooth engine operation. It also extends engine life. Proper adjustments are key.

| Risk | Impact |

|---|---|

| Engine Damage | Excessive wear, oil leaks, engine failure |

| Valve Timing Issues | Poor efficiency, valve damage |

- Regular checks prevent engine damage.

- Proper adjustments maintain valve timing.

- Understand risks to avoid costly repairs.

Proper Torque Specifications

Proper torque specifications are vital for hydraulic lifters. Over tighten hydraulic lifters can cause serious damage. Following the right guidelines ensures optimal performance.

Manufacturer Guidelines

Each manufacturer provides specific torque settings. These settings are crucial for the lifters’ longevity. Always refer to the manual before tightening.

Here is a table outlining some common torque specifications:

| Manufacturer | Torque (lb-ft) |

|---|---|

| Brand A | 18-22 |

| Brand B | 20-25 |

| Brand C | 15-20 |

Importance Of Precision

Precision is key for hydraulic lifters. Incorrect torque can lead to engine problems. It is vital to use a torque wrench for accuracy.

Here are some tips to ensure precision:

- Use a calibrated torque wrench

- Follow the manufacturer’s guidelines strictly

- Double-check the torque settings

Proper torque ensures the engine runs smoothly. It prevents costly repairs and extends the life of the lifters.

Tools For Correct Tightening

Using the right tools ensures proper tightening of hydraulic lifters. Over-tightening can cause damage. Correct tools help achieve the perfect balance.

Torque Wrench Usage

A torque wrench is essential for precise tightening. It measures the force applied to bolts. This ensures bolts are tightened to the manufacturer’s specifications.

Follow these steps for using a torque wrench:

- Set the desired torque level.

- Place the wrench on the bolt.

- Apply steady pressure until the wrench clicks.

Using a torque wrench prevents both under and over-tightening. It is a must-have tool in any mechanic’s toolbox.

Specialized Automotive Tools

Other specialized automotive tools also play a crucial role. These tools are designed for specific tasks.

Here are some examples:

| Tool Name | Function |

|---|---|

| Feeler Gauge | Measures gap sizes |

| Valve Spring Compressor | Compresses valve springs |

| Dial Indicator | Measures small distances |

Using these tools ensures accurate adjustments. This prevents costly mistakes and improves engine performance.

Diy Adjustment Tips

Adjusting hydraulic lifters yourself can save you money. It also ensures your engine runs smoothly. Follow these simple tips to avoid over-tightening and damaging your lifters.

Step-by-step Adjustment Guide

- Prepare Your Tools: Gather a wrench, feeler gauge, and screwdriver.

- Locate the Lifters: Find the hydraulic lifters in your engine.

- Remove the Valve Cover: Carefully take off the valve cover using a wrench.

- Identify the Rocker Arms: Look for the rocker arms connected to the lifters.

- Adjust the Lifters: Use a screwdriver to turn the adjustment screw. Move it until there is slight resistance.

- Check Clearance: Use a feeler gauge to measure the clearance. Ensure it matches the manufacturer’s specs.

- Tighten the Lock Nut: Secure the adjustment by tightening the lock nut with a wrench.

- Replace the Valve Cover: Put the valve cover back on and secure it.

Common Mistakes To Avoid

- Over-Tightening: Do not apply too much force. It can damage the lifters.

- Ignoring Manufacturer Specs: Always follow the manufacturer’s clearance specs.

- Using Incorrect Tools: Ensure your tools are the right size and type.

- Skipping Steps: Follow each step in order for a proper adjustment.

- Not Checking Clearance: Always measure the clearance with a feeler gauge.

By following these DIY adjustment tips, you can prevent common mistakes. This will help you avoid over-tightening hydraulic lifters.

When To Seek Professional Help

Over tightening hydraulic lifters can cause serious engine problems. Recognizing when to seek professional help is crucial. DIY fixes may lead to more damage. Knowing the signs and finding a qualified mechanic can save you time and money.

Signs That You Need An Expert

- Unusual Engine Noise: Clicking or tapping sounds suggest lifter issues.

- Engine Performance: Reduced power or misfires can be signs.

- Oil Contamination: Metal shavings in oil indicate internal damage.

- Excessive Valve Lash: Loose valve components need immediate attention.

Finding A Qualified Mechanic

Choosing the right mechanic is essential for fixing hydraulic lifters. Here are some tips:

- Check Certifications: Look for ASE-certified mechanics.

- Read Reviews: Online reviews can help find reputable services.

- Ask for Recommendations: Friends and family often know good mechanics.

- Compare Prices: Get quotes from multiple shops.

| Criteria | Importance |

|---|---|

| Certification | High |

| Experience | High |

| Customer Reviews | Medium |

| Price | Medium |

Long-term Maintenance For Hydraulic Lifters

Maintaining hydraulic lifters is crucial for your engine’s health. Proper upkeep ensures smooth operation and extends their lifespan. Regular checks and adjustments help avoid costly repairs.

Regular Inspection Schedules

Inspecting hydraulic lifters regularly helps identify potential issues early. Follow a consistent inspection schedule to keep them in good condition.

- Check hydraulic lifters every 10,000 miles.

- Listen for unusual noises during engine operation.

- Look for signs of wear and tear.

Regular checks ensure your lifters remain efficient. Document all inspections and findings to track their condition over time.

Ensuring Lifter Longevity

Proper maintenance practices ensure hydraulic lifters last longer. Follow these steps to maximize their lifespan:

- Use high-quality oil to reduce wear.

- Change the oil filter regularly.

- Avoid over-tightening the lifters.

High-quality oil reduces friction and prevents damage. Changing the oil filter keeps the oil clean, protecting the lifters. Over-tightening can cause significant harm, so follow manufacturer guidelines.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 5,000 miles |

| Filter Replacement | Every 5,000 miles |

| Lifter Inspection | Every 10,000 miles |

Following these maintenance tasks helps in ensuring the longevity of your hydraulic lifters. Keep a record of all maintenance activities for reference.

Hydraulic Lifter Myths Debunked

Hydraulic lifters play a crucial role in engines. Many myths surround their maintenance. Let’s debunk some common beliefs about over-tighten hydraulic lifters.

Myth Vs. Reality

Some believe to over-tighten hydraulic lifters is necessary. This is a myth. Over-tightening can damage the lifters. Proper adjustment is key.

Another myth is that tighter lifters improve performance. In reality, this can lead to engine issues. Properly adjusted lifters ensure smooth engine operation.

Fact-checking Common Beliefs

Fact: Hydraulic lifters need precise adjustment. Too tight or too loose affects performance.

Myth: Tighter lifters mean better engine power. Fact: Over-tightening can cause engine damage.

Myth: Tightening lifters eliminates noise. Fact: Correct adjustment reduces noise, not over-tightening.

| Myth | Reality |

|---|---|

| Tighter lifters improve performance | Can cause engine issues |

| Over-tightening is necessary | Proper adjustment is key |

| Tightening eliminates noise | Correct adjustment reduces noise |

Maintaining hydraulic lifters properly ensures engine health. Avoid over-tightening for best results.

Case Studies: The Consequences Of Over Tightening

Over tighten hydraulic lifters can cause serious damage. Real-life examples show these mistakes lead to engine failures. This section explores these cases and the lessons learned.

Real-life Engine Failures

Let’s look at some real-life engine failures caused by over tightening:

| Case | Vehicle | Consequence |

|---|---|---|

| Case 1 | Ford Mustang | Valve Damage |

| Case 2 | Chevrolet Camaro | Broken Push Rods |

| Case 3 | Dodge Charger | Engine Misfire |

Case 1: A Ford Mustang owner noticed a tapping noise. The engine lost power. Upon inspection, the valves were found damaged. The cause was over tightened hydraulic lifters.

Case 2: A Chevrolet Camaro had broken push rods. The engine ran rough. The mechanic discovered the hydraulic lifters were too tight. This caused excess pressure on the push rods.

Case 3: A Dodge Charger experienced an engine misfire. The lifters were over tightened. This prevented proper valve operation, leading to the misfire.

Lessons Learned

- Proper torque is crucial for hydraulic lifters.

- Over tightening can cause severe engine damage.

- Always follow the manufacturer’s torque specifications.

By reviewing these cases, you can see the importance of correct installation. Avoiding over tightening prevents costly repairs and engine failures.

Can You Damage Hydraulic Lifters By Overtightening?

Yes, overtightening hydraulic lifters can cause damage. It leads to improper valve operation and increased wear. Always follow the manufacturer’s torque specifications to avoid issues.

What Are Signs Of Overtightened Hydraulic Lifters?

Signs include noisy valves, poor engine performance, and excessive wear. These symptoms indicate the lifters aren’t functioning correctly. Addressing the issue promptly can prevent further damage.

How Do You Properly Tighten Hydraulic Lifters?

To properly tighten hydraulic lifters, follow the manufacturer’s torque specifications. Use a torque wrench for accuracy. Ensuring correct tightness prevents engine problems and prolongs lifter life.

Can Overtightening Hydraulic Lifters Affect Engine Performance?

Yes, overtightening hydraulic lifters can negatively affect engine performance. It can lead to improper valve operation. This results in reduced efficiency and potential engine damage.

Conclusion

Over-tightening hydraulic lifters can lead to engine damage and performance issues. Proper adjustment is crucial for optimal operation. Always follow manufacturer guidelines for precise settings. Regular maintenance ensures longevity and efficiency. Avoid common mistakes to keep your engine running smoothly.

Protect your investment by understanding the importance of correct hydraulic lifter adjustments.